Products

Ebil Tech

Pallet Rack

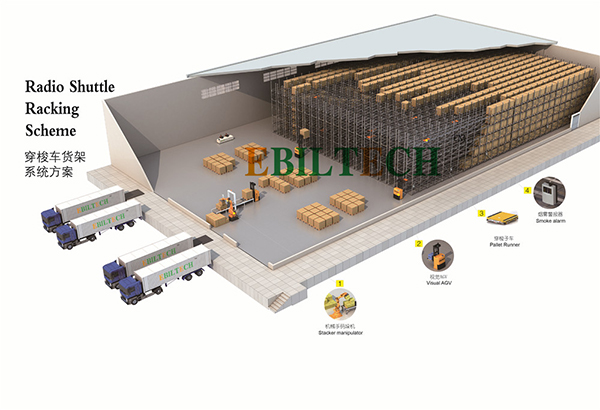

Pallet Rack is one of our products, we can provide one-stop storage system solutions and products, our products also include Four-Directional Shuttle Rack, VNA Pallet Racking System, Material Handling Robot, Mezzanine Rack, Teardrop-Style Rack, Beam Racking System, Metal sheet rack horizontal, Warehouse Radio Shuttle, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Newcastle upon Tyne (UK), Saint Pierre and Miquelon, Milan (Lombardy, Italy), Luxembourg, Gabon, San Marino, and so on. We are looking forward to cooperate with you. If you are interested in Pallet Rack.

A pallet rack, also known as a pallet racking system, is a type of warehouse storage system designed to store and organize palletized goods. It is one of the most common and widely used types of racking systems in warehouses and distribution centers.

Pallet racks are available in various configurations and sizes to accommodate different types of pallets, load capacities, and warehouse layouts. They are versatile and can be customized to meet specific storage requirements. Pallet racks are widely used to store a wide range of goods, from consumer products to industrial materials, and are a fundamental component of efficient warehouse storage systems.

Key features of a pallet rack include:

1. Uprights: Uprights are the vertical columns or frames that provide the main support for the pallet rack system. They are typically made of steel and come in various heights, widths, and load capacities. Uprights have evenly spaced holes or slots along their height, allowing for the insertion of load beams.

2. Load Beams: Load beams are horizontal components that connect the uprights and provide support for the pallets. They are inserted into the slots on the uprights and can be adjusted vertically in order to accommodate different pallet heights. Load beams are available in various lengths and load capacities to handle different weight requirements.

3. Pallet Supports or Wire Decking: Pallet supports or wire decking are optional accessories that can be placed on the load beams to provide a stable surface for the pallets. They help distribute the weight of the load evenly and prevent pallets from sagging between the beams. Wire decking consists of wire mesh panels that allow for better visibility and airflow.

4. Load Capacity: Pallet racks are designed to support specific load capacities, which depend on factors such as the type of uprights, load beams, and decking used. The load capacity of a pallet rack system is determined by the manufacturer and should not be exceeded to ensure safe storage.

5. Accessibility: Pallet racks allow for easy access to each pallet, making it convenient for inventory management and order picking. Forklifts or other material handling equipment can be used to load and unload pallets from the rack system. Selective pallet racks provide direct access to each pallet without the need to move other pallets.

6. Space Utilization: Pallet racks are designed to maximize vertical storage space in a warehouse. By utilizing the height of the facility, pallet racks allow for efficient use of available space. They can be stacked multiple levels high, depending on the height of the facility and the strength of the rack system.

There are several types of pallet racks available, each designed to suit different storage needs and warehouse configurations. Here are some common types of pallet racks:

1. Selective Pallet Rack: Selective pallet rack is the most common and widely used type of pallet rack. It provides direct access to each pallet stored in the system, allowing for easy inventory management and order picking. Selective racks are versatile and can accommodate different pallet sizes and load capacities.

2. Drive-In Pallet Rack: Drive-in pallet rack is designed for high-density storage and is suitable for storing large quantities of the same SKU. It eliminates the need for aisles between rack bays, as forklifts can drive into the rack structure to deposit or retrieve pallets. Drive-in racks operate on a Last-In, First-Out (LIFO) principle.

3. Drive-Through Pallet Rack: Similar to drive-in racks, drive-through pallet rack systems also offer high-density storage. However, they allow for forklifts to enter the rack structure from both ends, enabling First-In, First-Out (FIFO) inventory rotation. Drive-through racks provide better accessibility and flexibility compared to drive-in racks.

4. Push-Back Pallet Rack: Push-back pallet rack systems offer high-density storage with a Last-In, First-Out (LIFO) inventory rotation. Pallets are loaded onto nesting carts that are pushed back along inclined rails. When a new pallet is loaded, it pushes the previous one deeper into the rack. Push-back racks are suitable for storing multiple pallets of the same SKU.

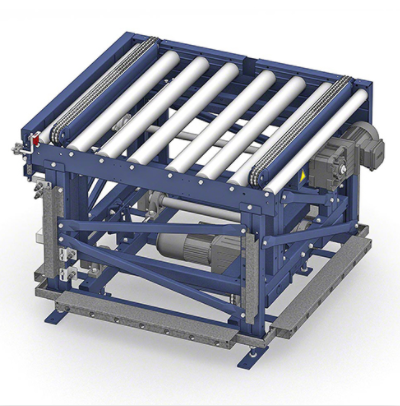

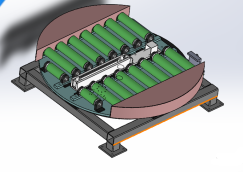

5. Pallet Flow Rack: Pallet flow rack, also known as gravity flow rack, utilizes inclined roller tracks or wheels to create a dynamic flow system. Pallets are loaded at the higher end of the rack and flow down to the picking face using the force of gravity. Pallet flow racks operate on a First-In, First-Out (FIFO) principle, ensuring automatic stock rotation.

6. Cantilever Pallet Rack: Cantilever pallet rack is designed for the storage of long, bulky, or irregularly shaped items such as lumber, pipes, or furniture. It consists of vertical columns with horizontal arms extending from them, providing unobstructed access to each item. Cantilever racks are commonly used in industries such as construction, manufacturing, and retail.

7. Double-Deep Pallet Rack: Double-deep pallet rack systems store two pallets deep, one behind the other, which requires specialized forklifts with extended reach. This type of rack offers higher storage density compared to selective racks but reduces the accessibility to rear pallets.

8. Mezzanine Pallet Rack: Mezzanine pallet racks involve the installation of a raised platform or additional floor within the warehouse space. It creates extra storage space above or below the mezzanine structure, utilizing vertical space while maintaining accessibility to the lower level.

These are some of the main types of pallet racks commonly used in warehouses and distribution centers. The choice of pallet rack system depends on factors such as the type of goods being stored, inventory turnover, available space, accessibility requirements, and budget constraints. It is important to consider the specific needs of the warehouse and consult with experts to determine the most suitable pallet rack solution.

The pricing of pallet rack systems can vary based on several factors, including the type of pallet rack, size, configuration, load capacity, material, and the supplier or manufacturer. Pallet rack systems come in various types, such as selective pallet racking, drive-in racking, push-back racking, and more.

1. Selective Pallet Racking:

- Price Range: $75 to $200 per pallet position (rack bay) for new systems.

- Factors Affecting Price: Height, width, and depth of the uprights, number of levels, load capacity, additional accessories (e.g., wire mesh decking, pallet supports), and any customization requirements.

2. Drive-in Pallet Racking:

- Price Range: $150 to $400 per pallet position (rack bay) for new systems.

- Factors Affecting Price: Height, width, and depth of the uprights, number of levels, load capacity, number of pallets deep, and any customization requirements.

3. Push-Back Pallet Racking:

- Price Range: $200 to $500 per pallet position (rack bay) for new systems.

- Factors Affecting Price: Height, width, and depth of the uprights, number of levels, load capacity, number of pallets deep, and any customization requirements.

4. Cantilever Pallet Racking:

- Price Range: $50 to $150 per arm (depending on length) for new systems.

- Factors Affecting Price: Height, number of arms per upright, arm length, load capacity, and any customization requirements.

Please keep in mind that these prices are estimates and can vary significantly depending on factors specific to your needs, such as the size of the project, the supplier, and any additional requirements or customization. It's recommended to contact suppliers or manufacturers directly to get accurate and up-to-date pricing. They can provide detailed quotations based on your specific requirements and help you determine the most suitable pallet rack system for your storage needs.