Products

Ebil Tech

Selective Rack

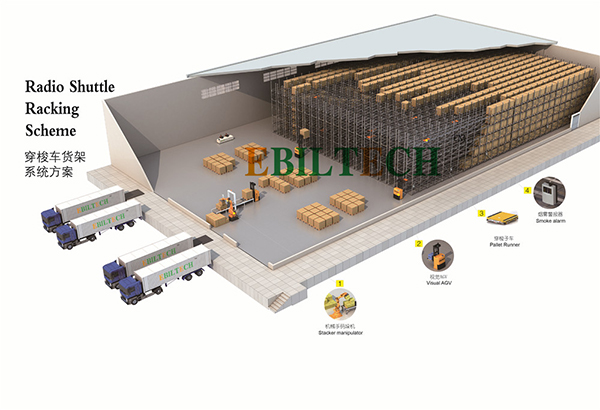

Selective Rack is one of our products, we can provide one-stop storage system solutions and products, our products also include Telescoping arm rack, RGV System, Four-Directional Shuttle Car, VNA Warehouse Rack, Stacker Crane, Expandable cantilever rack, Metal Rack, Pallet Flow Racking System, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Abuja (Nigeria), Jeddah (Saudi Arabia), Ghana, Solomon Islands, Udmurt, Tegucigalpa (Honduras), and so on. We are looking forward to cooperate with you. If you are interested in Selective Rack.

Selective rack, also known as selective pallet rack, is the most common type of racking system used in warehouses and distribution centers. It offers direct access to every pallet stored, allowing for high selectivity and flexibility in inventory management.

Here's an overview of selective rack and its types:

1. Selective Rack:

- Structure: Selective rack consists of upright frames and horizontal beams. The frames are vertical supports with evenly spaced slots or holes to adjust the beam height. The beams are inserted into the slots to create levels for pallet storage.

- Accessibility: Selective rack provides direct access to every pallet, meaning each pallet can be individually accessed without moving others. This allows for easy stock rotation, fast picking, and efficient inventory management.

- Versatility: Selective rack is suitable for a wide range of products, including palletized loads, boxes, cartons, and various sizes and shapes of items. It offers flexibility in accommodating different product dimensions and weights.

- Load Capacity: The load capacity of selective rack varies based on factors such as the quality of materials, beam design, and configuration. It can handle light to heavy loads, typically ranging from a few hundred to several thousand pounds per level.

2. Single-Deep Selective Rack:

- Configuration: In single-deep selective rack, pallets are stored back-to-back in single rows. Each pallet is accessible from the aisle in front of the rack.

- Advantages: Single-deep selective rack provides high selectivity, allowing easy access to each pallet. It is suitable for applications with a wide variety of SKUs and frequent product turnover.

3. Double-Deep Selective Rack:

- Configuration: Double-deep selective rack involves storing pallets two-deep, with one pallet positioned behind the other. The front pallet is accessible directly from the aisle, while the rear pallet requires the front pallet to be removed first for access.

- Advantages: Double-deep selective rack offers increased storage density compared to single-deep rack, making it more space-efficient. It is suitable for applications with larger quantities of the same SKU and a lower need for immediate access to each pallet.

4. Push-Back Rack:

- Configuration: Push-back rack is a form of selective rack with inclined rails or carts that allow pallets to be stored and retrieved from the same aisle. Pallets are loaded from the front and pushed back by subsequent pallets. When a pallet is unloaded, the others roll forward.

- Advantages: Push-back rack offers higher storage density than single-deep selective rack while maintaining selectivity. It allows for dense storage with fewer aisles required, making it suitable for applications with multiple SKUs and medium inventory turnover.

These are the main types of selective rack commonly used in warehouses. Each type offers different benefits in terms of accessibility, storage density, and inventory management. The choice of selective rack type depends on the specific needs, available space, and characteristics of the stored products in a particular warehouse or distribution center.