Products

Ebil Tech

Radio Shuttle Rack

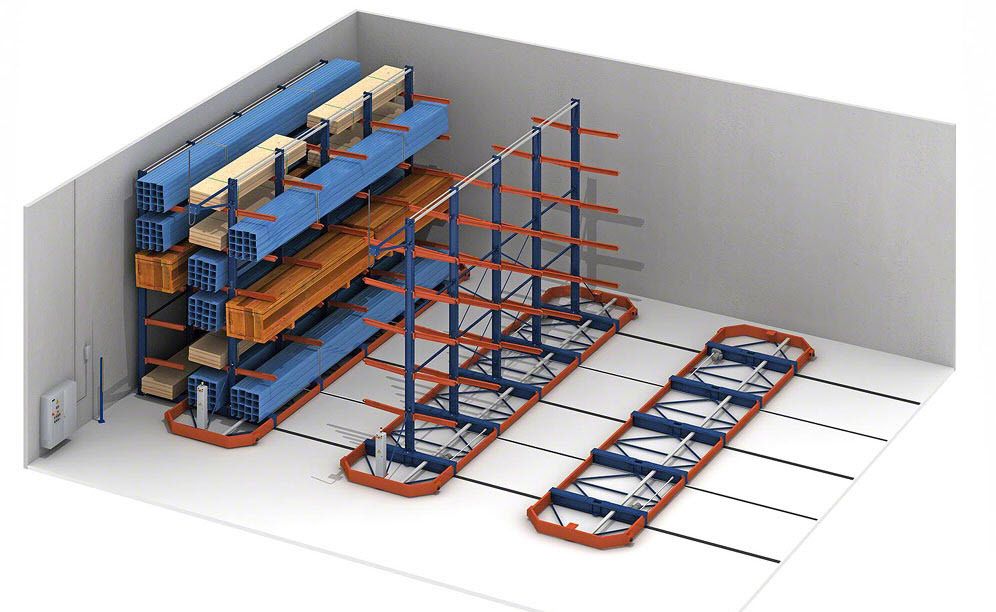

Radio Shuttle Rack is one of our products, we can provide one-stop storage system solutions and products, our products also include Smart Pallet Shuttle, ASRS, Telescoping Cantilever Shelving, Gravity Flow Rack, Shuttle Carrier System, Pallet Mole Rack, Shuttle System Solution, Tear Drop Style Racking, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Hans Island, Hala'ib Triangle, Spain, San Salvador (El Salvador), Amsterdam (Netherlands), Crimea, and so on. We are looking forward to cooperate with you. If you are interested in Radio Shuttle Rack.

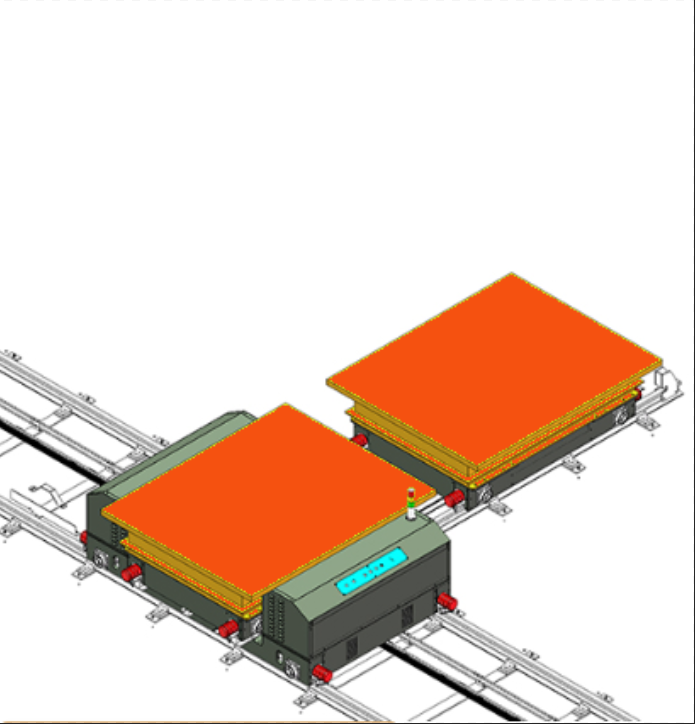

A Radio Shuttle Rack, also known as a radio shuttle pallet racking system, is an automated high-density storage solution that utilizes a remote-controlled shuttle device to transport pallets within the racking structure. It is designed to optimize storage capacity, improve efficiency, and reduce labor requirements in warehouse operations.

Here are the key features and types of Radio Shuttle Racks:

1. Structure: A Radio Shuttle Rack system consists of upright frames, horizontal beams, and specially designed shuttle devices. The shuttle devices are battery-powered and equipped with wheels to move along the guide rails within the racking structure. They can lift and lower pallets and have sensors for accurate positioning.

2. Remote Control: The shuttle devices are controlled remotely by an operator using a radio frequency (RF) remote control or a central control system. This allows for precise movement and positioning of the shuttle within the racking system.

3. High Storage Density: Radio Shuttle Racks offer high storage density by eliminating the need for aisles between each rack. The shuttle device operates within the racking structure, allowing for deep storage of multiple pallets in each lane. This maximizes the use of available space and increases overall storage capacity.

4. FIFO and LIFO Configurations: Radio Shuttle Racks can be configured to operate in both First-In, First-Out (FIFO) and Last-In, First-Out (LIFO) modes. In the FIFO configuration, the shuttle retrieves the oldest pallets first, while in the LIFO configuration, it retrieves the most recently loaded pallets.

5. Single-Depth and Double-Depth Shuttles: There are two main types of Radio Shuttle Racks based on the depth of the shuttle operation. Single-depth shuttles are designed to operate within a single pallet position, while double-depth shuttles can operate within two pallet positions (one behind the other). Double-depth shuttles provide increased storage capacity but may require a specialized forklift or reach truck for loading and unloading.

6. Shuttle-Cranes: Shuttle-cranes combine the functionality of a Radio Shuttle Rack with a crane system. They use a crane to lift and move the shuttle devices vertically, allowing for the shuttle to operate on multiple levels within the racking structure. Shuttle-cranes provide high-density storage and increased flexibility in terms of vertical storage.

7. Enhanced Efficiency: Radio Shuttle Racks automate the movement of pallets, reducing the need for manual labor and improving operational efficiency. They enable faster loading and unloading times, as well as efficient stock retrieval. Additionally, they can integrate with warehouse management systems for inventory tracking and optimization.

Radio Shuttle Racks are particularly beneficial for warehouses with high-volume storage needs, fast-moving inventory, and limited available space. By optimizing storage density and improving operational efficiency, they help maximize warehouse productivity and streamline inventory management processes.