Products

Ebil Tech

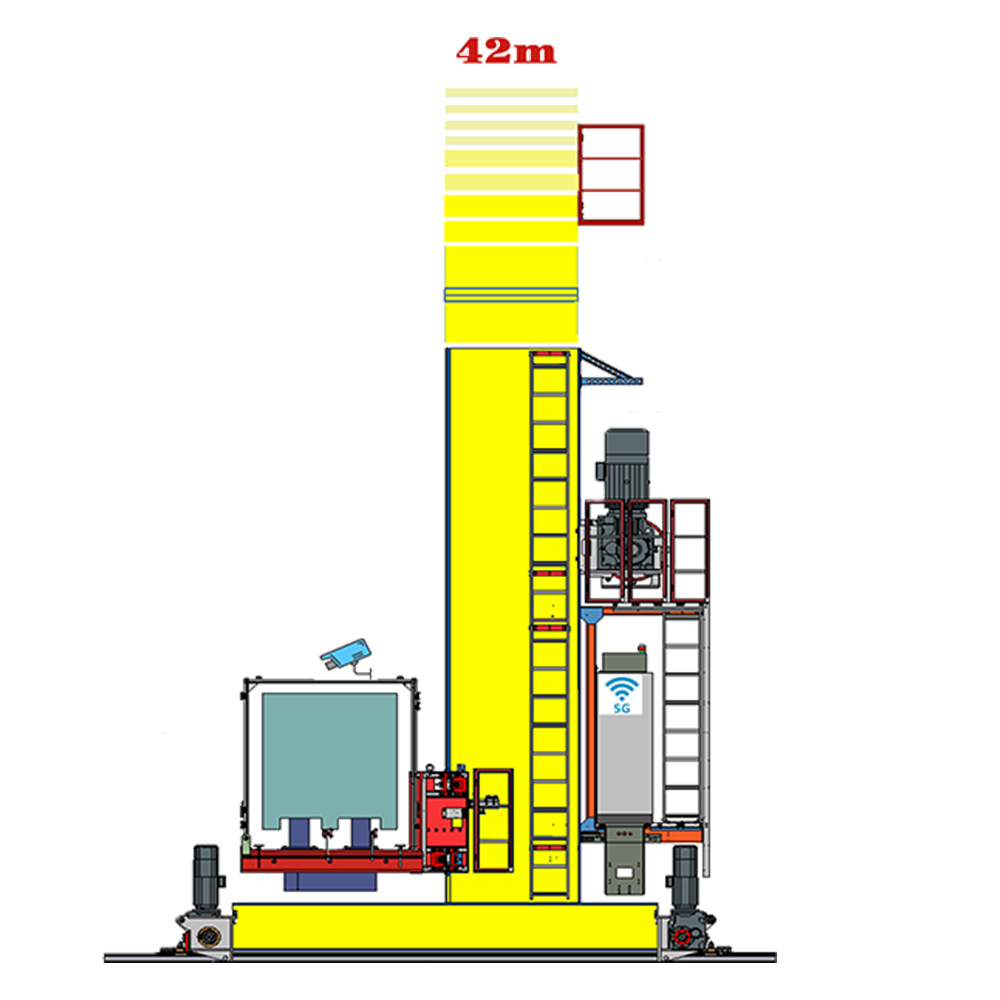

Warehouse Pallet Racking

Warehouse Pallet Racking is one of our products, we can provide one-stop storage system solutions and products, our products also include Teardrop Warehouse Rack, Medium Duty Shelving, Steel Work Platform, Warehouse Rack System, Shuttle System, Drawer Rack for Sheets, Guided Transport Vehicle, Intelligent Stacker, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Norfolk Island, Tunisia, Wellington (New Zealand), Oslo (Norway), San Luis Potos¡§?, Montreal (Quebec, Canada), and so on. We are looking forward to cooperate with you. If you are interested in Warehouse Pallet Racking.

Warehouse pallet racking refers to a system of storage racks specifically designed to store and organize palletized goods in a warehouse or distribution center. It is a versatile and widely used solution for maximizing storage capacity, facilitating efficient inventory management, and improving accessibility to stored products.

Here are the key features and applications of warehouse pallet racking:

Features of Warehouse Pallet Racking:

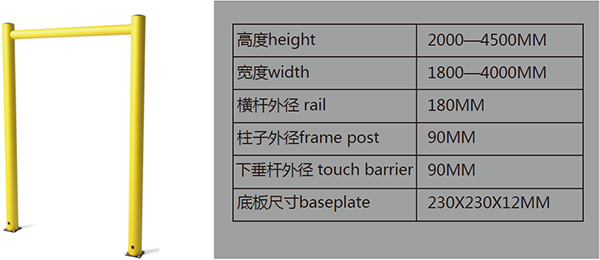

1. Upright Frames: Warehouse pallet racking consists of vertical upright frames that provide support and stability to the rack system. These frames are typically made of steel and are anchored to the floor to ensure structural integrity.

2. Horizontal Beams: Horizontal beams connect the upright frames, creating the levels or shelves on which pallets are placed. The beams are adjustable, allowing for flexibility in accommodating pallets of various sizes and weights.

3. Selective Accessibility: Warehouse pallet racking offers selective accessibility, meaning each pallet can be accessed individually without the need to move others. This allows for efficient inventory management, stock rotation, and order picking.

4. High Load Capacity: Pallet racking systems are designed to handle heavy loads. The load capacity of the racks depends on factors such as the beam strength, upright height, and the quality of the materials used. Different rack configurations and beam lengths can accommodate different load capacities.

5. Safety Measures: Warehouse pallet racking often includes safety features such as beam connectors, safety pins, and locking devices to prevent accidental dislodgement of beams. Additionally, rack protection accessories like column protectors, rack guards, and aisle end barriers can be installed to enhance warehouse safety.

6. Various Configurations: Pallet racking systems offer various configurations to suit different warehouse layouts and storage requirements. The most common configurations include selective racks, drive-in/drive-through racks, push-back racks, and pallet flow racks.

Applications of Warehouse Pallet Racking:

1. Bulk Storage: Warehouse pallet racking is ideal for bulk storage of large quantities of the same product. It allows for high-density storage by stacking multiple pallets vertically, maximizing the use of available space.

2. Order Fulfillment: Pallet racking systems facilitate efficient order fulfillment processes by providing easy access to stored goods. They can be integrated with picking systems such as forklifts, conveyors, and order pickers to streamline the order picking operations.

3. Inventory Management: Pallet racking enables systematic inventory management by providing a well-organized storage system. It allows for proper categorization, labeling, and tracking of products, leading to improved inventory accuracy and efficiency.

4. Just-in-Time (JIT) Inventory: Warehouse pallet racking supports JIT inventory management practices by ensuring quick and easy access to products when needed. JIT systems aim to minimize excess inventory and maximize efficiency by delivering goods to the production line or customers on-demand.

5. Retail and Distribution Centers: Pallet racking is commonly used in retail and distribution centers to store a wide variety of products. It facilitates efficient storage and retrieval of goods, optimizing the flow of inventory and reducing handling time.

6. Manufacturing and Production: Pallet racking systems are utilized in manufacturing facilities to store raw materials, work-in-progress (WIP) items, and finished goods. They enable efficient material handling and support the production flow.

When implementing warehouse pallet racking, it is important to consider factors such as the weight and dimensions of the palletized goods, the available space, the desired storage density, and any specific safety regulations or local building codes. Consulting with professionals experienced in pallet racking design and installation is recommended to ensure a safe and efficient storage solution tailored to your specific needs.