Products

Ebil Tech

Pallet Rack System

Pallet Rack System is one of our products, we can provide one-stop storage system solutions and products, our products also include Box Shuttle, Drive Through Racking, Mid-Duty Shelving, Heavy Duty Pallet Rack System, Multi-Layer Shuttle, Storage Shuttle Car, Steel Industrial Platform, Selective Pallet Rack, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Berlin (Germany), Afghanistan, Istanbul (Turkey), Budapest (Hungary), New York (New York State, USA), Chad, and so on. We are looking forward to cooperate with you. If you are interested in Pallet Rack System.

A pallet rack system is a type of storage system designed to store and organize palletized goods in warehouses, distribution centers, and industrial facilities. It provides efficient use of vertical space and allows for easy access to stored items. Here's some information about pallet rack systems:

1. Design and Components:

- Uprights: Uprights are vertical columns that provide the main support structure of the rack system. They are typically made of steel and are connected to the warehouse floor or a base plate for stability.

- Beams: Beams are horizontal load-bearing components that connect to the uprights. They create the levels or shelves on which the pallets rest. Beams are adjustable in height to accommodate different pallet sizes.

- Wire Decking: Wire decking is a mesh-like platform that sits on the pallet rack beams. It provides additional support for pallets and improves safety by preventing smaller items from falling through the racks.

- Pallet Supports: Pallet supports are bars or beams that span between the front and back beams of a pallet rack. They provide additional support and stability to pallets placed directly on the rack beams.

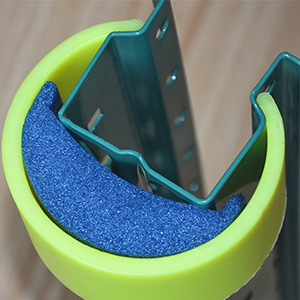

- Accessories: Pallet rack systems can include various accessories such as row spacers, column protectors, and rack guards to enhance safety, stability, and organization within the system.

2. Types of Pallet Rack Systems:

- Selective Pallet Rack: Selective pallet rack is the most common type of pallet rack system. It allows for direct access to each pallet and provides flexibility in terms of pallet size and storage configuration.

- Drive-In/Drive-Through Rack: Drive-in and drive-through racks are designed for high-density storage. They allow forklifts to drive directly into the rack system to deposit or retrieve pallets. Drive-in racks have a single entry point, while drive-through racks have entry points on both ends.

- Push Back Rack: Push back racks are a type of dynamic storage system where pallets are stored on wheeled carts that are pushed back along inclined rails. This allows for higher storage density and first-in-last-out (FILO) inventory rotation.

- Pallet Flow Rack: Pallet flow racks use gravity to move pallets along inclined rollers or wheels. Pallets are loaded from one end and flow to the other, facilitating efficient stock rotation based on the first-in-first-out (FIFO) principle.

- Cantilever Rack: Cantilever racks are designed for the storage of long, bulky, or irregularly shaped items. They have horizontal arms that extend outward from upright columns, providing open-front storage without vertical obstructions.

3. Advantages of Pallet Rack Systems:

- Increased Storage Capacity: Pallet rack systems maximize vertical space utilization, allowing for efficient storage of large quantities of palletized goods.

- Accessibility and Selectivity: Selective pallet rack systems provide direct access to each pallet, making it easy to locate and retrieve specific items.

- Versatility: Pallet rack systems can accommodate various pallet sizes, weights, and configurations, making them suitable for a wide range of industries and applications.

- Scalability: Pallet rack systems are modular and can be expanded or reconfigured as storage needs change over time.

- Improved Warehouse Efficiency: Pallet rack systems facilitate organized storage, efficient inventory management, and streamlined material handling processes.

4. Considerations:

- Load Capacity: Ensure that the pallet rack system is designed and rated to handle the weight of the pallets and loads you plan to store.

- Warehouse Layout and Space Optimization: Consider the layout of your warehouse, aisle widths, and clearances to determine the most suitable pallet rack system configuration.

- Safety Measures: Adhere to safety guidelines by using proper load signs, installing rack protectors, and conducting regular inspections to prevent accidents and ensure the stability of the rack system.

- Material Handling Equipment: Consider the type and capacity of forklifts or other material handling equipment used in your facility to ensure compatibility with the pallet rack system.

When implementing a pallet rack system, it's recommended to consult with storage system experts or suppliers who can assess your specific storage requirements, evaluate your warehouse layout, and provide guidance on the most suitable pallet rack system that meets your needs in terms of capacity, accessibility, and safety.