Products

Ebil Tech

Pallet Shuttle

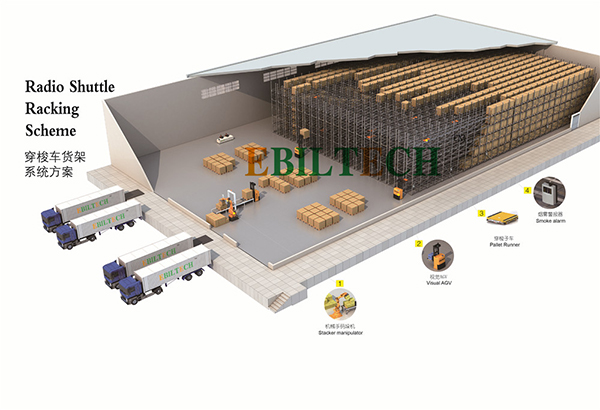

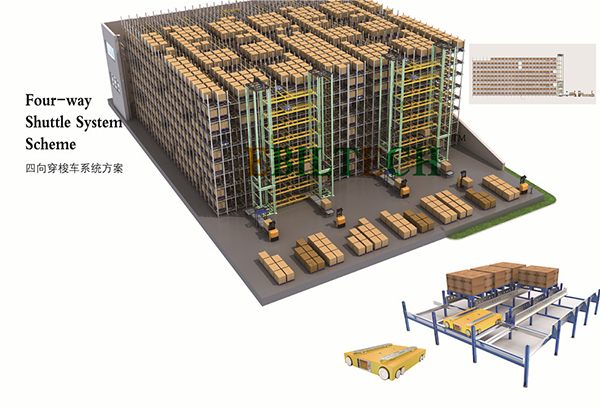

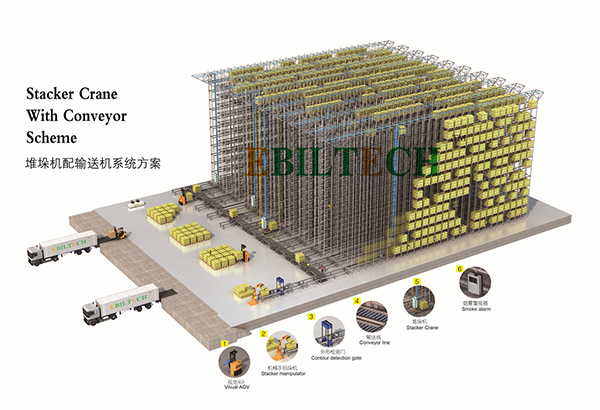

Pallet Shuttle is one of our products, we can provide one-stop storage system solutions and products, our products also include Steel Mezzanine Platform, Pallet Runner Rack, Robotic Storage Rack, Roll-Out Rack, Four-Directional Shuttle Rack, Narrow Aisle Warehouse Rack, Four Way Shuttle, Heavy Duty Rack System, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Luxembourg, Singapore (Singapore), British Indian Ocean Territory, Melilla, Burundi, Kosovo, and so on. We are looking forward to cooperate with you. If you are interested in Pallet Shuttle.

A Pallet Shuttle, also known as a Pallet Shuttle System or Pallet Runner, is an automated solution used for high-density storage and retrieval of palletized goods in a warehouse or distribution center. It is designed to operate within specially designed racking systems and is particularly useful for applications where a large number of pallets need to be stored or retrieved quickly and efficiently.

Pallet Shuttle systems offer benefits such as increased storage capacity, improved throughput, reduced labor requirements, and enhanced inventory control. They optimize material flow, eliminate the need for forklifts within the storage lanes, and allow for efficient use of warehouse space.

The specific design and capabilities of a Pallet Shuttle system may vary depending on the manufacturer or system provider. Different companies may have their own proprietary technologies, variations, or alternative names for similar systems.

Here are the key features and components of a Pallet Shuttle system:

1. Pallet Shuttle Device: The Pallet Shuttle device is a motorized unit that runs on rails or tracks within the storage lanes of a racking system. It is controlled remotely and moves pallets horizontally along the lanes, storing or retrieving them from their designated storage positions. The Pallet Shuttle device can be battery-powered and operates using wireless communication.

2. Racking Structure: The racking structure of a Pallet Shuttle system consists of deep storage lanes specifically designed to accommodate the Pallet Shuttle devices. These lanes are typically equipped with guide rails or tracks that allow the Pallet Shuttle device to move smoothly and position the pallets accurately within the storage bays.

3. Pallet Storage and Retrieval: Pallets are loaded into the storage lanes at the entry points using forklifts or other loading equipment. The Pallet Shuttle device then transports the pallets within the lane, placing them in the appropriate storage positions. When a pallet needs to be retrieved, the Pallet Shuttle device moves beneath it, lifts it, and carries it to the lane's exit for removal.

4. Remote Control and Communication: The Pallet Shuttle device is controlled remotely using a handheld remote control or a centralized control system. Operators send commands to the Pallet Shuttle device to perform tasks such as pallet loading, unloading, and movement within the storage lanes. Communication between the control system and the Pallet Shuttle device is typically wireless, allowing for real-time updates and instructions.

5. Safety Features: Pallet Shuttle systems incorporate safety features to ensure the safe operation of the device and protect personnel and equipment. These may include sensors to detect obstacles or other pallets in the lane, emergency stop buttons, and safety zones to prevent unauthorized access to the Pallet Shuttle's path.

The specific type of pallet shuttle used in a warehouse or distribution center can vary based on the manufacturer and the design of the system. However, there are generally two main types of pallet shuttles commonly used in shuttle-based storage systems:

1. Rail-Guided Pallet Shuttle: This type of pallet shuttle operates on a set of rails or tracks within the storage lanes. The shuttle is guided and propelled along the rails by a drive mechanism, which can be electrically powered. The rail-guided pallet shuttle moves horizontally within the lane and can access multiple storage positions along the track.

2. Free-Moving Pallet Shuttle: Unlike the rail-guided shuttle, the free-moving pallet shuttle operates without rails or tracks. It is equipped with its own drive mechanism, usually powered by batteries or an electric motor. The free-moving shuttle can autonomously navigate within the storage lanes, moving horizontally and vertically to access different storage positions.

Both types of pallet shuttles are designed to transport pallets within the warehouse racking system, but they differ in terms of their guidance and propulsion mechanisms. Rail-guided shuttles offer precise and controlled movement along the fixed tracks, while free-moving shuttles provide more flexibility and adaptability in navigating through the storage lanes.

The choice between rail-guided and free-moving pallet shuttles depends on factors such as the specific requirements of the warehouse, the layout of the racking system, and the desired level of automation and flexibility. Each type has its own advantages and considerations, so it's important to evaluate the specific needs and constraints of the warehouse when selecting the appropriate type of pallet shuttle for the shuttle-based storage system.