Products

Ebil Tech

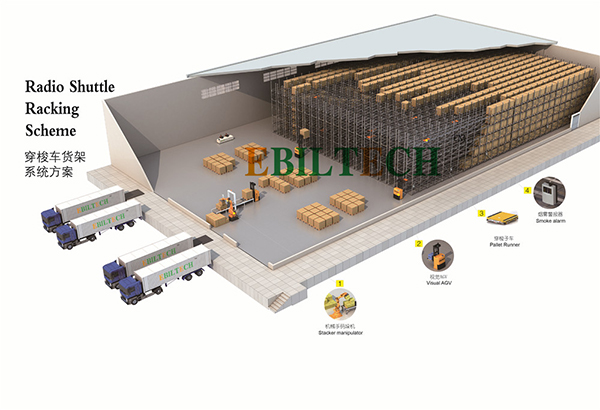

Shuttle Rack

Shuttle Rack is one of our products, we can provide one-stop storage system solutions and products, our products also include Teardrop Pallet Rack System, Mezzanine Floor Rack, Automatic Stacker, Medium-Duty Pallet Rack, Narrow Aisle Storage Rack, VNA Pallet Racking, Satellite Shuttle System, Pallet Flow Racking, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Crimea, Jan Mayen, Saint Vincent and the Grenadines, Ankara (Turkey), Cleveland (United States), Altay, and so on. We are looking forward to cooperate with you. If you are interested in Shuttle Rack.

Shuttle rack systems, also known as shuttle racking or radio shuttle racking, are innovative and high-density storage solutions that utilize shuttle devices to handle and transport pallets within a racking structure. Here's some information about shuttle rack systems:

1. Profiles and Types:

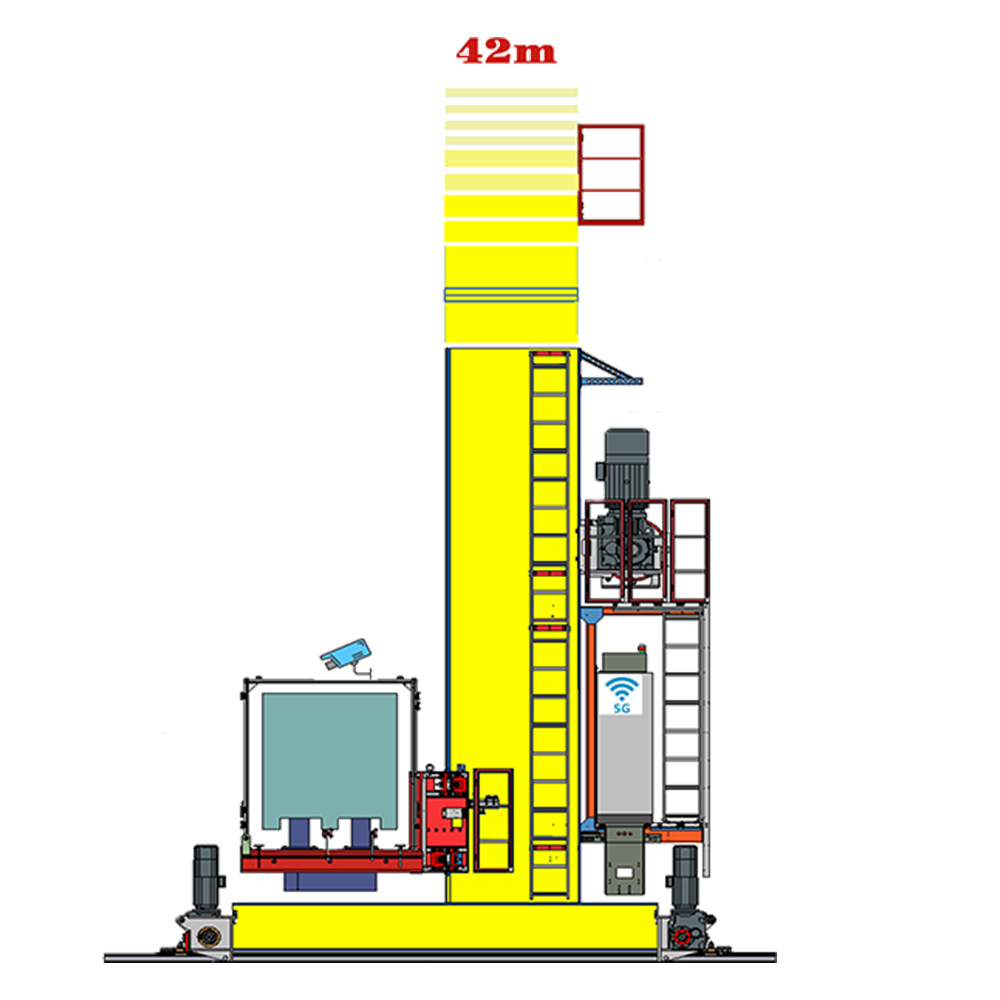

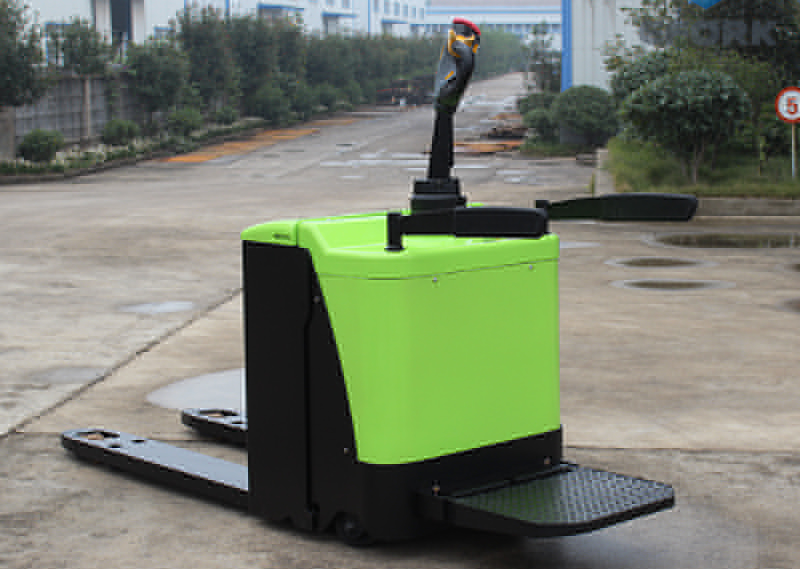

- Shuttle Device: The shuttle device is a motorized and remote-controlled unit that operates within the racking structure. It is equipped with wheels or rollers to move horizontally along the racks, and it can lift and lower pallets as needed.

- Racking Structure: Shuttle rack systems are typically designed with selective pallet racking or drive-in racking configurations. The racks provide vertical support for pallet storage and guide the movement of the shuttle devices.

- Control System: The shuttle devices are controlled by a central control system, which communicates with the warehouse management system (WMS) and manages the movement and positioning of the shuttles.

2. Applications:

- High-Density Storage: Shuttle rack systems are ideal for warehouses or distribution centers with limited floor space that require efficient storage of a large number of pallets.

- Cold Storage: The ability of shuttle rack systems to operate effectively in cold storage environments makes them well-suited for industries such as food and beverage, pharmaceuticals, and logistics.

- FIFO or LIFO Operations: Shuttle rack systems can be configured to support both first-in, first-out (FIFO) and last-in, first-out (LIFO) inventory management strategies, depending on the specific application and requirements.

- Multi-Temperature Storage: Shuttle rack systems can be used for multi-temperature storage, allowing for the segregation and efficient retrieval of pallets with different temperature requirements.

3. Advantages:

- Increased Storage Capacity: Shuttle rack systems provide high-density storage by maximizing vertical space and utilizing deep lane configurations.

- Efficient Pallet Handling: The shuttle devices can handle pallets within the racking structure, reducing the need for forklifts to enter the racks for loading and unloading.

- Enhanced Throughput: Shuttle rack systems enable simultaneous handling of multiple pallets, resulting in increased throughput and reduced waiting times.

- Improved Order Picking: The system allows for efficient and accurate order picking by automatically retrieving and delivering pallets to pick stations.

- Flexibility and Scalability: Shuttle rack systems can be customized and adapted to specific warehouse layouts, pallet sizes, and load capacities. They are also scalable, allowing for future expansion or reconfiguration.

4. Approximate Costs:

- The cost of shuttle rack systems can vary depending on factors such as the size of the system, the number of shuttle devices required, the racking configuration, the load capacity, and the specific supplier or manufacturer.

- As an approximate range, the cost of a shuttle rack system can start from around $400 to $800 per pallet position, including the shuttle devices, racking structure, control system, and installation. However, it is important to note that the actual cost will depend on the specific project requirements and should be obtained from suppliers or material handling equipment providers through detailed quotations.

It is recommended to consult with suppliers or material handling equipment providers to obtain accurate pricing based on your specific needs and project requirements. They can provide detailed quotations, assist in designing the most suitable shuttle rack system for your warehouse, and offer guidance on installation and maintenance.