Products

Ebil Tech

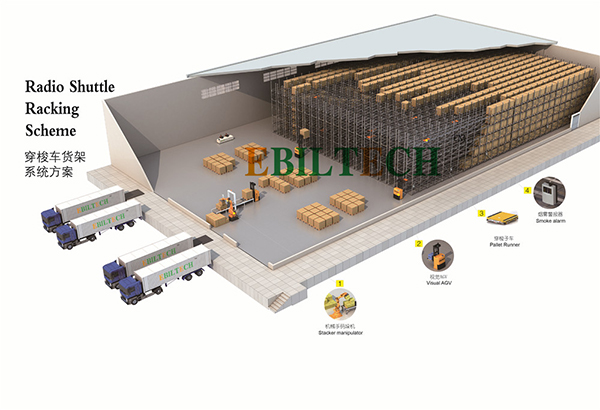

Fully Automated Racking System

Fully Automated Racking System is one of our products, we can provide one-stop storage system solutions and products, our products also include Motorized Adjustable Cantilever Rack, Medium Duty Shelving Units, Warehouse Rack, Cassette Drawer Rack, Shuttle Carrier System, Drive-In Pallet Rack, VNA Pallet Rack System, Retrieval Crane Rack, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Kampala (Uganda), Iraq, Labuan (Malaysia), Tajikistan, Birmingham (UK), Curitiba/Curitiba (Brazil), and so on. We are looking forward to cooperate with you. If you are interested in Fully Automated Racking System.

The Fully Automated Racking System, also known as an automated storage and retrieval system (ASRS), is a sophisticated and advanced type of industrial storage system. It combines various technologies and automation components to automate the storage and retrieval of goods or inventory in a warehouse or distribution center.

A Fully Automated Racking System typically consists of the following key components:

1. Racking Structure: The racking structure forms the framework for storing the goods. It can be designed in various configurations to accommodate different types of items, such as pallets, containers, or individual products.

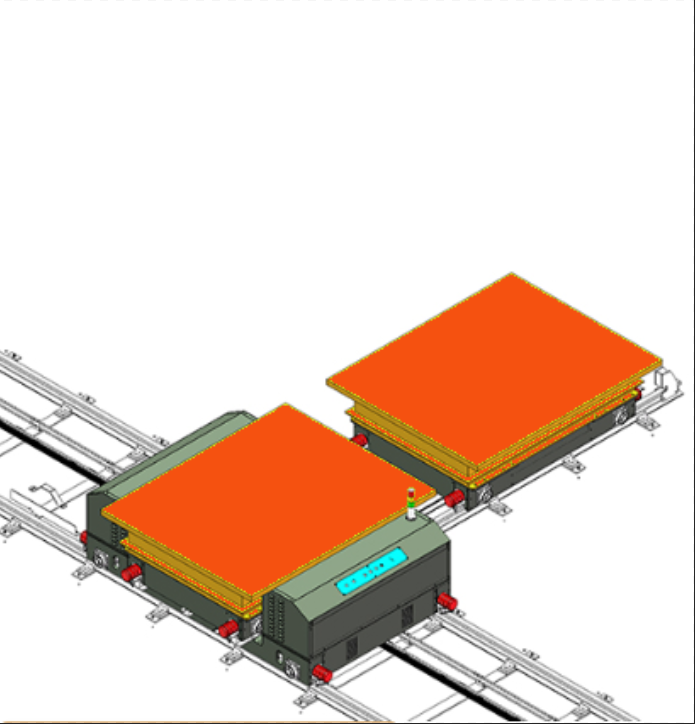

2. Automated Storage and Retrieval Equipment: This includes robotic vehicles, stacker cranes, or shuttles that are responsible for moving within the racking structure to retrieve or store items. These automated machines are equipped with lifting devices or robotic arms to handle the goods.

3. Conveyor Systems: Conveyor systems are often integrated into Fully Automated Racking Systems to transport goods between different areas of the warehouse, such as the loading and unloading stations or connecting workstations.

4. Warehouse Management System (WMS): A WMS is a software system that controls and manages the entire Fully Automated Racking System. It oversees inventory tracking, order management, and coordinates the movement of the automated equipment to optimize storage and retrieval operations.

5. Sensors and Safety Systems: Fully Automated Racking Systems incorporate various sensors, such as proximity sensors, barcode scanners, or vision systems, to detect and monitor the position of goods and ensure smooth and safe operation. Safety systems are implemented to prevent collisions or accidents within the system.

The benefits of a Fully Automated Racking System include:

1. Increased Efficiency: By automating the storage and retrieval processes, a Fully Automated Racking System eliminates the need for manual labor and improves operational efficiency. It reduces the time required to locate and retrieve items, leading to faster order fulfillment and increased productivity.

2. Space Optimization: Fully Automated Racking Systems maximize vertical space utilization, making efficient use of available warehouse space. They can stack goods higher than manual systems, thereby increasing storage capacity.

3. Improved Inventory Control: With the integration of a Warehouse Management System, a Fully Automated Racking System provides real-time inventory visibility, accurate tracking of items, and efficient inventory management. It helps reduce stock discrepancies, improves stock rotation, and minimizes the risk of inventory obsolescence.

4. Enhanced Safety: Fully Automated Racking Systems incorporate advanced safety features to minimize the risk of accidents or damage to goods. Sensor-based technologies and safety interlocks ensure safe operation within the system.

Fully Automated Racking Systems are suitable for high-volume, high-density storage environments where precision, efficiency, and space optimization are crucial. They are commonly used in industries such as e-commerce, manufacturing, distribution, and logistics, where large quantities of goods need to be stored and retrieved in a timely and automated manner.