Products

Ebil Tech

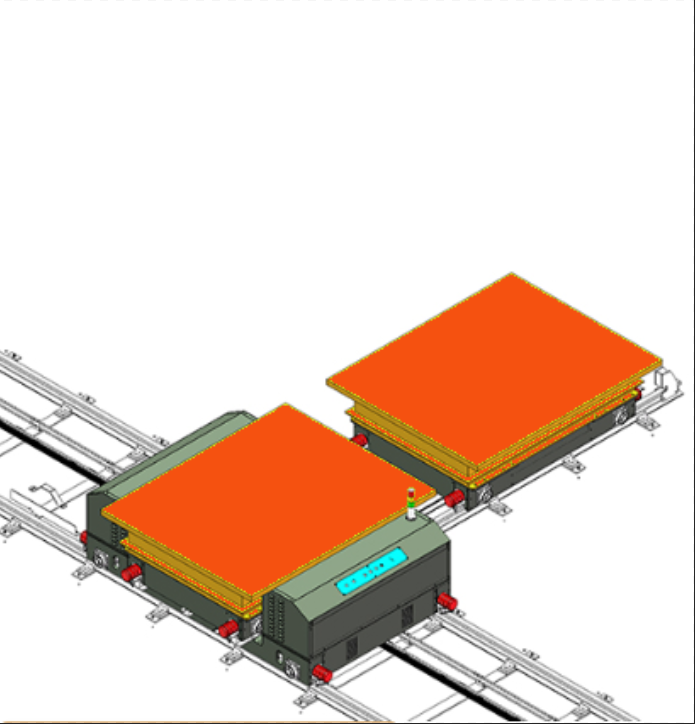

Satellite Shuttle Storage System

Satellite Shuttle Storage System is one of our products, we can provide one-stop storage system solutions and products, our products also include High-Density Racking System, Multi-Directional Shuttle Car, Four-Way Shuttle Car, Gravity Flow Rack, Automatic long bars storage system, Automated Mobile Storage System, Vertical Lift, Beam Rack, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Saint Lucia, Kuwait City (Kuwait), Hartford (United States), Baltimore (United States), Nepal, Johannesburg (South Africa), and so on. We are looking forward to cooperate with you. If you are interested in Satellite Shuttle Storage System.

A Satellite Shuttle Storage System, also known as a Satellite Shuttle Rack System or simply Shuttle Rack System, is an advanced automated storage and retrieval system (AS/RS) used in warehouses or distribution centers to optimize storage density and improve operational efficiency. It utilizes satellite shuttles to transport and store pallets or other unitized loads within the racking system.

The Satellite Shuttle Storage System offers several benefits, including increased storage capacity, improved inventory management, reduced labor requirements, and enhanced operational efficiency. It is commonly used in industries such as food and beverage, retail, logistics, and manufacturing where space optimization and efficient material handling are critical.

The specific features and capabilities of a Satellite Shuttle Storage System can vary depending on the manufacturer and the specific requirements of the warehouse or distribution center.

Here are some key features and characteristics of a Satellite Shuttle Storage System:

1. Satellite Shuttles: The system consists of specialized satellite shuttles that operate within the racking system. These shuttles, which are equipped with lifting and movement capabilities, travel along the racking aisles to transport pallets or loads in and out of storage positions.

2. Racking System: The racking system used in a Satellite Shuttle Storage System typically consists of high-density storage racks with multiple levels. The shuttles move horizontally along the rack aisles, accessing different storage positions to deposit or retrieve loads.

3. Remote Control and Guidance: The satellite shuttles are controlled and guided by a central control system. The system directs the shuttles to the appropriate storage locations based on the inventory management system or warehouse management system (WMS) instructions.

4. Pallet Handling: The Satellite Shuttle Storage System is designed to handle standard pallets or other unitized loads. The shuttles can lift and transport loads within the racking system, allowing for efficient storage and retrieval operations.

5. High Storage Density: The system enables high-density storage by optimizing the use of vertical space in the warehouse. The shuttles can access multiple levels within the racking system, maximizing storage capacity and reducing the footprint required for storage.

6. FIFO or LIFO Operation: The Satellite Shuttle Storage System can operate in either the First-In, First-Out (FIFO) or Last-In, First-Out (LIFO) mode, depending on the specific requirements of the stored goods and the operational needs of the facility.

7. Automation and Integration: The system is highly automated, minimizing the need for manual intervention in the storage and retrieval process. It can be integrated with other warehouse systems, such as conveyor systems, order picking systems, or inventory management systems, to optimize overall warehouse operations.