Products

Ebil Tech

Multi-Layer Shuttle

Multi-Layer Shuttle is one of our products, we can provide one-stop storage system solutions and products, our products also include Shuttle Rack, Teardrop Style Rack, Satellite Shuttle System, Teardrop Rack Shelving, Multi Shuttle Racking System, Motorized adjustable cantilever racks, Pallet Flow Rack System, Teardrop Selective Rack, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as San Pedro Sula (Honduras), Valencia (Spain), Dominica, Riyadh (Saudi Arabia), Cocos (Keeling) Islands, Sao Paulo (Sao Paulo State, Brazil), and so on. We are looking forward to cooperate with you. If you are interested in Multi-Layer Shuttle.

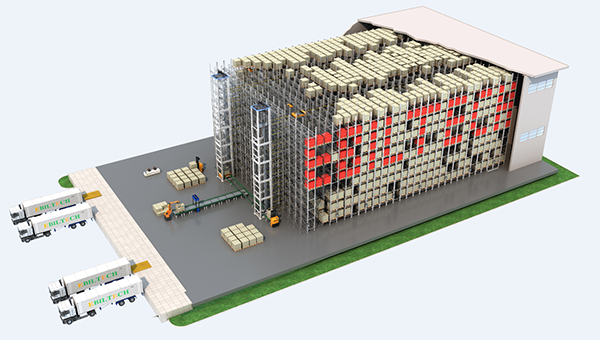

A Multi-Layer Shuttle system consists of a series of horizontal layers or levels within a high-rise rack structure. Each layer is equipped with a shuttle device that can move horizontally along the length of the storage lanes. The Multi-Layer Shuttle is designed to optimize vertical storage space and improve the efficiency of material handling operations.

The Multi-Layer Shuttle system offers advantages such as increased storage capacity, efficient space utilization, and enhanced picking and storage operations. It is particularly suitable for warehouses or distribution centers dealing with a large volume of products and seeking to optimize storage density and material handling efficiency.

The key features and functions of a Multi-Layer Shuttle system include:

1. Multiple Storage Levels: The system is designed with multiple horizontal layers or tiers within the rack structure. Each layer can accommodate storage lanes for pallets, totes, or other unit loads.

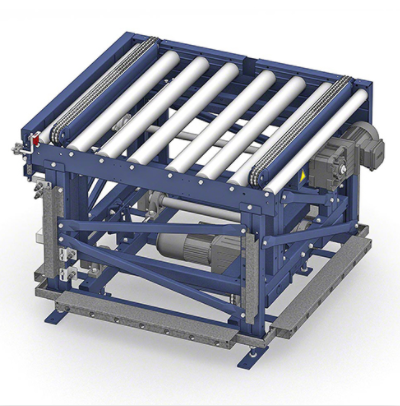

2. Shuttle Devices: Each layer of the system is equipped with shuttle devices that can move horizontally along the storage lanes. These shuttle devices are usually battery-powered and can autonomously transport loads to and from designated storage locations.

3. Vertical Lifts: The Multi-Layer Shuttle system often incorporates vertical lifts or elevators that connect the different layers. These lifts allow the shuttle devices to move between the layers and access different storage levels.

4. High-Density Storage: The Multi-Layer Shuttle system enables high-density storage by utilizing the vertical space efficiently. It allows for the storage of multiple pallets or loads in each lane and can handle a large number of SKUs or product variations.

5. Automation and Control: The system is typically controlled by a central computerized control system that coordinates the movement of the shuttle devices, vertical lifts, and other equipment. It can interface with warehouse management systems (WMS) to facilitate inventory control and order fulfillment.

6. Increased Throughput: Multi-Layer Shuttle systems are designed for high-speed and high-throughput operations. The shuttle devices can quickly retrieve and store loads, contributing to faster order processing and improved warehouse productivity.