Products

Ebil Tech

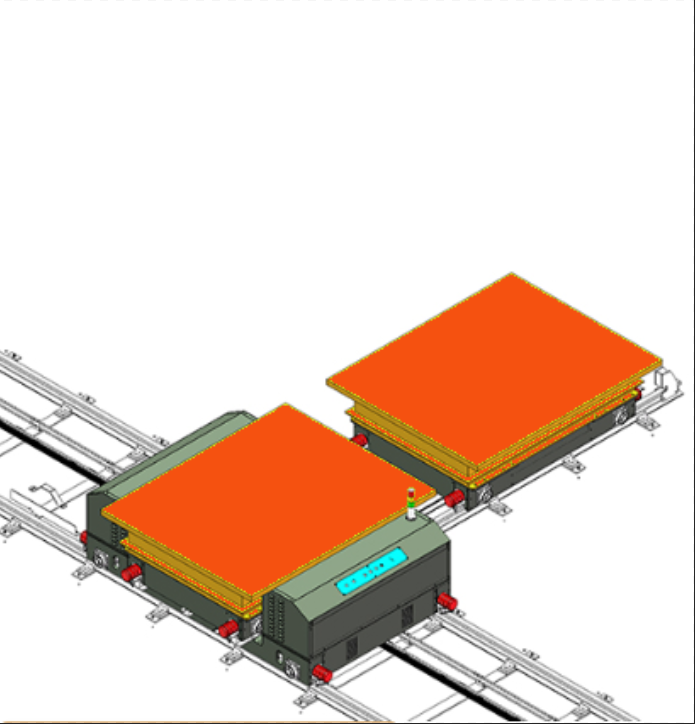

AS/RS Shuttle

AS/RS Shuttle is one of our products, we can provide one-stop storage system solutions and products, our products also include Industrial Steel Platform, Storage Steel Platform, Mobile Shelving, Steel Platform, Warehouse Automation Equipment, Metal Rack, Drive In Racking System, Telescoping cantilever racking system, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Louisville (United States), Halifax (Canada), Greece, Saudi Arabia, Georgetown (Guyana), Saba Island, and so on. We are looking forward to cooperate with you. If you are interested in AS/RS Shuttle.

AS/RS Shuttle, also known as automated storage and retrieval system Shuttle, is a type of automated material handling system commonly used in warehouses and distribution centers. It is designed to efficiently store and retrieve items or loads within a high-density storage system.

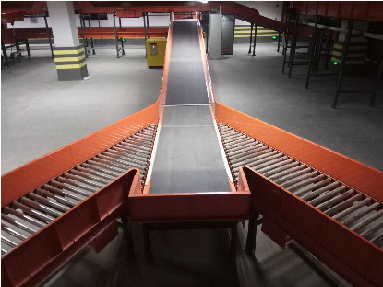

AS/RS Shuttles typically consist of a network of robotic shuttles or vehicles that move horizontally along tracks or rails within a racking system. These shuttles are responsible for carrying and transferring goods between storage locations and picking stations.

AS/RS Shuttle systems offer numerous benefits, including increased storage capacity, improved inventory accuracy, reduced labor costs, and enhanced operational efficiency. By automating the storage and retrieval processes, they minimize human intervention, eliminate errors, and optimize the overall material handling operations within a warehouse or distribution center.

The key features and functionalities of AS/RS Shuttle:

1. Storage and Retrieval: AS/RS Shuttles are designed to store items in designated storage locations within the racking system. They can autonomously navigate through the storage lanes, locating and depositing items at specific locations. Similarly, when an item needs to be retrieved, the shuttles locate it within the system and transport it to the designated retrieval point.

2. High-Density Storage: AS/RS Shuttles are employed in high-density storage systems, such as stacker cranes or rack structures. They operate within the vertical space between the racks, maximizing storage capacity by utilizing both the height and width of the facility. This allows for efficient space utilization and increased storage density.

3. Automated Operation: AS/RS Shuttles operate autonomously, guided by advanced control systems and navigation algorithms. They can communicate with the central control system and receive instructions for storage or retrieval tasks. The system manages the movements of the shuttles, optimizing their paths and coordinating their operations to ensure efficient and synchronized material flow.

4. Flexibility and Scalability: AS/RS Shuttle systems are known for their flexibility and scalability. They can be customized to accommodate different load sizes and types, making them suitable for a wide range of industries and applications. The system can be easily expanded or reconfigured to adapt to changing storage needs or business requirements.

5. Integration with Warehouse Management Systems: AS/RS Shuttles are often integrated with Warehouse Management Systems (WMS) or Warehouse Control Systems (WCS). This integration allows for real-time inventory management, order processing, and optimization of storage and retrieval operations. It enables efficient coordination between the AS/RS Shuttles and other material handling equipment within the warehouse.

AS/RS Shuttle systems are utilized in various industries and sectors where efficient and automated storage and retrieval of goods are crucial. Here are some examples of industries that commonly employ AS/RS Shuttle systems:

1. E-commerce and Retail: With the rapid growth of e-commerce and the need for efficient order fulfillment, AS/RS Shuttle systems are widely used in e-commerce warehouses and retail distribution centers. These systems enable high-density storage of products and efficient retrieval for order picking and shipping.

2. Food and Beverage: The food and beverage industry often deals with perishable items and a wide range of SKUs. AS/RS Shuttle systems are utilized to store and retrieve inventory, ensuring proper inventory rotation based on expiration dates and optimizing space utilization in temperature-controlled environments.

3. Automotive: Automotive manufacturing and distribution facilities often rely on AS/RS Shuttle systems for storing and retrieving various automotive components, such as parts, tires, and sub-assemblies. These systems help manage the vast inventory of components efficiently and provide quick access for assembly lines.

4. Pharmaceuticals and Healthcare: AS/RS Shuttle systems play a critical role in pharmaceutical and healthcare industries, where precise inventory control and quick access to products are paramount. These systems ensure proper storage conditions, traceability, and efficient retrieval of medications, medical supplies, and healthcare equipment.

5. Logistics and Distribution: AS/RS Shuttle systems are extensively used in logistics and distribution centers to manage the storage and retrieval of goods for various industries. They optimize warehouse space, enhance inventory accuracy, and streamline order fulfillment processes for efficient logistics operations.

6. Manufacturing and Industrial: AS/RS Shuttle systems are implemented in manufacturing plants and industrial facilities to optimize material storage and retrieval processes. They enable efficient handling of raw materials, work-in-progress inventory, and finished goods, ensuring timely availability of components for production.

7. Third-Party Logistics (3PL): Third-party logistics providers heavily rely on AS/RS Shuttle systems to efficiently manage and store inventory for multiple clients. These systems enable secure and organized storage of goods from different industries and facilitate fast and accurate order fulfillment.

These systems have applications in various other sectors that require automated and high-density storage solutions to streamline their material handling operations.