Products

Ebil Tech

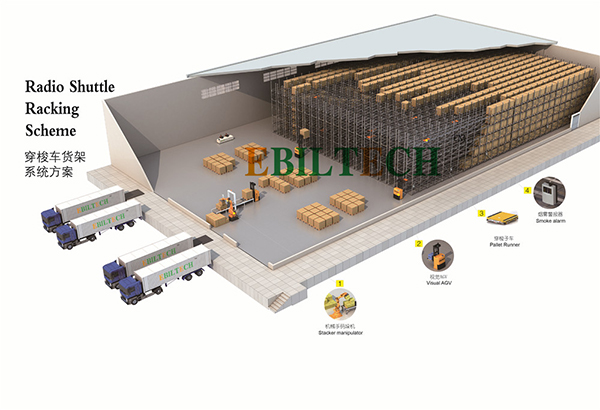

Retrieval Crane Rack

Retrieval Crane Rack is one of our products, we can provide one-stop storage system solutions and products, our products also include Medium-Sized Shelving, Heavy Duty Pallet Racking, Mezzanine Rack, Electric Mobile Shelving Systems, Mezzanine Racking, Electric extendable cantilever shelving, Shuttle Racking, Expandable cantilever rack, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Congo (Brazzaville), Penang (George Town), Rochester (United States), Tonga, Edinburgh (Scotland, UK), Nassau (Bahamas), and so on. We are looking forward to cooperate with you. If you are interested in Retrieval Crane Rack.

A retrieval crane rack, also known as an automated storage and retrieval system (AS/RS) with cranes, is a type of storage system that utilizes automated cranes to retrieve and store items within a rack structure. This system allows for high-density storage, efficient inventory management, and automated retrieval and replenishment processes.

Here are the key features and components of a retrieval crane rack:

1. Rack Structure: The retrieval crane rack consists of a tall and sturdy rack structure with multiple levels or tiers. The structure is designed to support the weight of stored items and provide stability for the automated cranes to operate within.

2. Automated Cranes: Retrieval crane racks are equipped with automated cranes that move horizontally along rails or tracks within the rack structure. These cranes are responsible for retrieving and storing items from designated storage locations within the rack. They typically utilize lifting mechanisms, such as forks or grippers, to handle and transport the items.

3. Control System: A sophisticated control system manages the operation of the retrieval crane rack. It coordinates the movement of the cranes, tracks inventory levels, and controls the retrieval and storage processes. The control system can be integrated with inventory management software, warehouse management systems (WMS), or other automation systems for seamless operation.

4. Storage and Retrieval Locations: The retrieval crane rack is divided into multiple storage locations, which can be shelves, bins, or pallet positions. These locations are organized in a grid pattern to optimize storage space. Each location is assigned a unique identifier to facilitate accurate retrieval and storage.

5. Inventory Management: The retrieval crane rack system tracks and manages inventory levels in real-time. The control system keeps a record of the location and quantity of stored items, allowing for efficient inventory management, accurate stock counts, and inventory replenishment.

Benefits of a retrieval crane rack system include:

- High-Density Storage: Retrieval crane racks provide high-density storage by utilizing vertical space efficiently. The automated cranes can retrieve and store items at multiple levels within the rack structure, maximizing storage capacity.

- Fast and Efficient Retrieval: The automated cranes can quickly and accurately retrieve items from their designated storage locations. This reduces the time and effort required for manual picking and improves order fulfillment speed.

- Improved Inventory Accuracy: With real-time inventory tracking and management, retrieval crane racks offer improved inventory accuracy. The system can automatically update inventory levels and provide accurate stock information, minimizing errors and improving inventory control.

- Space Optimization: Retrieval crane racks optimize the use of available space by utilizing vertical storage. This allows for a smaller footprint compared to traditional racking systems, making them suitable for facilities with limited floor space.

- Enhanced Safety: The use of automated cranes reduces the need for manual labor and minimizes the risk of accidents and injuries associated with manual handling. Safety features, such as obstacle detection sensors and emergency stop mechanisms, are typically incorporated into the system.

Retrieval crane racks are commonly used in various industries, including manufacturing, distribution centers, and warehouses that require high-density storage and efficient retrieval processes. They offer improved inventory management, space optimization, and streamlined operations through automation.