Products

Ebil Tech

Racks For Pallets Warehouse

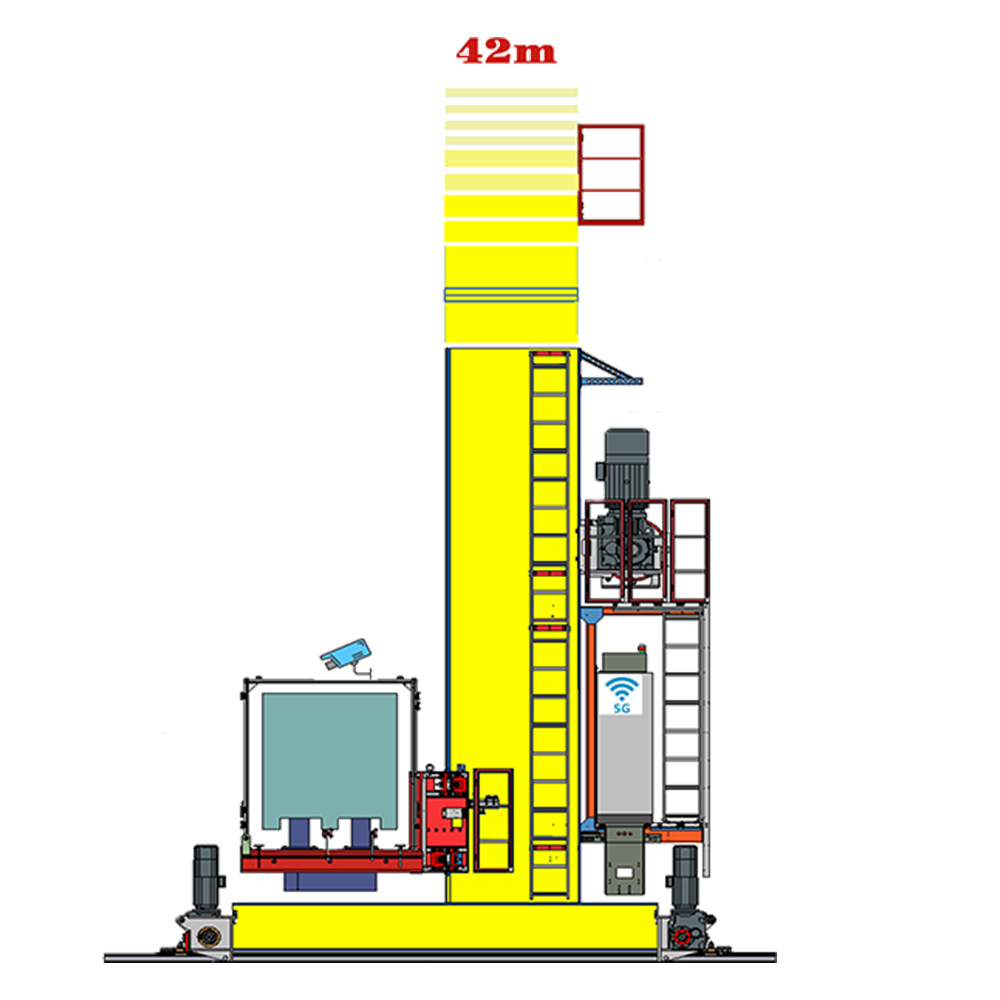

Racks For Pallets Warehouse is one of our products, we can provide one-stop storage system solutions and products, our products also include Multi-Directional Shuttle Racking System, Medium Duty Storage Racks, Warehouse Shuttle Car, FIFO Racking, Storage Pallet Racks, Flat Pallet Rack TRG, Industrial warehouse racking, Chilled Warehouse Rack, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Bucharest (Romania), Bologna (Italy), Guam, Bosnia and Herzegovina, Karelia, Glorioso Islands, and so on. We are looking forward to cooperate with you. If you are interested in Racks For Pallets Warehouse.

Racks for Pallets Warehouse Information

Racks for pallets, also known as pallet racking systems, are essential components of modern warehouses and storage facilities. They provide efficient and organized storage solutions for palletized goods, optimizing space utilization and facilitating easy access to inventory. Here is some information about racks for pallets warehouse:

Types of Pallet Racking Systems:

1. Selective Pallet Racks: Selective pallet racking is the most common type of pallet racking system. It consists of upright frames and horizontal beams that create individual levels for pallet storage. Selective racks offer direct access to each pallet, making them suitable for high selectivity and fast-moving inventory.

2. Drive-In/Drive-Through Racks: Drive-in and drive-through racks are designed for high-density storage. These systems eliminate aisles by allowing forklifts to drive directly into the rack structure. Drive-in racks have one entry point, while drive-through racks have entry points on both ends, enabling first-in, first-out (FIFO) or last-in, first-out (LIFO) inventory management.

3. Push Back Racks: Push back racks offer high-density storage with a Last-In, First-Out (LIFO) inventory rotation system. They use a series of nested carts on inclined rails, allowing pallets to be stored and retrieved from the same aisle. When a new pallet is loaded, it pushes the existing pallets back, and when a pallet is retrieved, the remaining pallets move forward.

4. Pallet Flow Racks: Pallet flow racks use gravity to move pallets from the loading end to the picking end. They consist of slightly inclined roller tracks with brake rollers or speed controllers. As the front pallet is removed, the next pallet moves forward automatically. Pallet flow racks are ideal for high-density storage and FIFO inventory management.

5. Cantilever Racks: Cantilever racks are designed for storing long, bulky, or irregularly shaped items such as lumber, pipes, or furniture. They feature horizontal arms that extend from upright columns, providing easy access to the stored items. Cantilever racks are commonly used in lumber yards, hardware stores, and manufacturing facilities.

Key Considerations for Pallet Racking Systems:

1. Load Capacity: Pallet racking systems come with different load capacity ratings. It is crucial to consider the weight and dimensions of the palletized goods being stored to ensure that the racking system can handle the required load.

2. Warehouse Layout and Space: The layout and available space in the warehouse play a significant role in determining the type and configuration of pallet racking systems. It is important to consider factors such as aisle width, ceiling height, and the overall floor plan to optimize storage capacity.

3. Accessibility and Inventory Management: Different types of pallet racking systems offer varying levels of accessibility and inventory management methods. Consider the frequency of item retrieval, inventory turnover, and the desired inventory rotation system (FIFO or LIFO) to choose the most suitable racking system for your needs.

4. Safety Features: Pallet racking systems should incorporate safety features such as load beams with safety locks, column protectors, and safety signage. It is essential to adhere to safety guidelines and regulations to protect both personnel and stored goods.

Installation and Maintenance:

Professional installation and regular maintenance are crucial for the safe and efficient operation of pallet racking systems. It is recommended to engage experienced installation teams who can ensure that the racks are correctly assembled and secured. Regular inspections and maintenance should be conducted to identify any damage or issues and address them promptly to maintain the structural integrity and safety of the racking system.

Consulting with a reputable supplier or rack manufacturer is highly recommended when selecting and installing pallet racking systems. They can provide expert advice, customized solutions, and ongoing support to optimize your warehouse storage and enhance operational efficiency.