Products

Ebil Tech

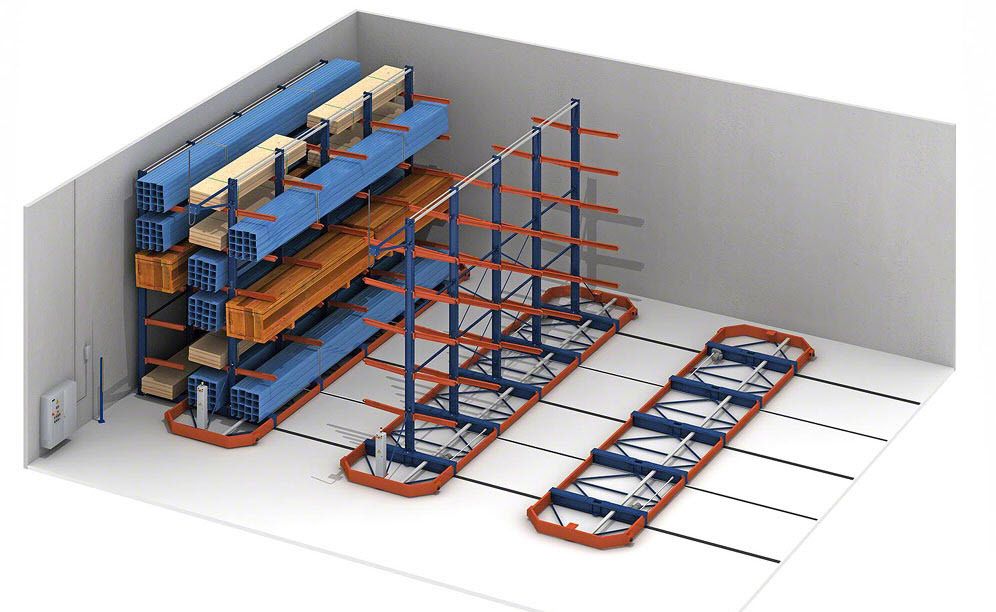

Gravity Pallet Racking

Gravity Pallet Racking is one of our products, we can provide one-stop storage system solutions and products, our products also include Radio Shuttle Racking System, Warehouse Drive-In Pallet Rack, Robotic Storage Rack, Eletric Double Column Stacker Crane, Material Lift, Multi-Lever Mezzanine Racking, Pallet Rack System, Warehouse Lift, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Frankfurt (Hesse, Germany), Manchester (UK), Chuvash, Zurich (Switzerland), Lima (Peru), Seattle (United States), and so on. We are looking forward to cooperate with you. If you are interested in Gravity Pallet Racking.

Gravity pallet racking, also known as gravity flow racking or gravity-fed racking, is a type of pallet racking system that uses the force of gravity to move pallets within the rack. It is designed for high-density storage and efficient order picking, especially for fast-moving products with a first-in, first-out (FIFO) inventory rotation.

Here is some information about gravity pallet racking:

Principle of Operation:

Gravity pallet racking operates on the principle of inclined roller tracks or wheels that allow pallets to flow smoothly from the loading end to the picking end. The racks are set at a slight incline, creating a gravity-driven flow system. Pallets are loaded from the higher end, and their weight and the slope of the tracks enable them to move gradually down to the lower end.

Key Components:

1. Roller Tracks/Wheels: Gravity flow racks feature inclined roller tracks or wheels that facilitate the movement of pallets. These tracks/wheels are typically made of steel or other durable materials and are designed to provide smooth and controlled flow.

2. Flow Rails: Flow rails are the channels or lanes on which the roller tracks or wheels are mounted. They guide the pallets along the desired path within the racking system.

3. Brake Systems: Gravity pallet racking systems often incorporate braking mechanisms to control the speed and movement of the pallets. These brakes help ensure safe and controlled flow, preventing pallets from colliding or moving too quickly.

Advantages of Gravity Pallet Racking:

1. High-Density Storage: Gravity flow racks maximize the use of vertical space and allow for deep storage, significantly increasing storage capacity compared to traditional static racking systems.

2. FIFO Inventory Rotation: Gravity racking systems facilitate the first-in, first-out (FIFO) inventory rotation method, ensuring that older stock is picked first, minimizing the risk of product expiration or obsolescence.

3. Efficient Order Picking: With gravity flow racks, products automatically move forward as the front pallet is picked, reducing the time and effort required for order picking. This improves productivity and minimizes congestion in picking aisles.

4. Stock Control and Visibility: Due to the nature of the system, gravity pallet racking offers better visibility and control over inventory levels, making it easier to monitor stock levels and replenishment needs.

Applications of Gravity Pallet Racking:

Gravity pallet racking is commonly used in industries and applications where high-density storage and efficient order picking are required. Some typical applications include:

- Food and Beverage: Gravity flow racks are ideal for storing food and beverage items that require FIFO rotation to maintain freshness and minimize waste.

- Pharmaceutical and Healthcare: These racks are suitable for storing pharmaceuticals, medical supplies, and healthcare products that have expiration dates or specific storage requirements.

- Distribution and Logistics: Gravity pallet racking is widely used in distribution centers and logistics operations to streamline order picking and improve overall efficiency.

- E-commerce and Fulfillment: The system is well-suited for e-commerce warehouses and fulfillment centers, where quick and accurate order fulfillment is essential.

It's important to note that gravity pallet racking requires careful planning and design to ensure the proper slope, track spacing, and load capacities are in place. Consulting with storage solution providers or rack manufacturers is recommended to determine the best configuration and ensure compliance with safety standards.