Products

Ebil Tech

Very Narrow Aisle Pallet Rack

Very Narrow Aisle Pallet Rack is one of our products, we can provide one-stop storage system solutions and products, our products also include Electric extendable cantilever shelving, Steel Mezzanine Racking, Adjustable Cantilever Rack, Metal Radio Shuttle Racking, Mother Shuttle And Satellite Shuttle System, Multi Shuttle Storage Rack, Mezzanine Floor Rack, ASRS Rack, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Isle of Man, Riga (Latvia), Panama, San Jose (United States), Mauritania, Kazan (Russia), and so on. We are looking forward to cooperate with you. If you are interested in Very Narrow Aisle Pallet Rack.

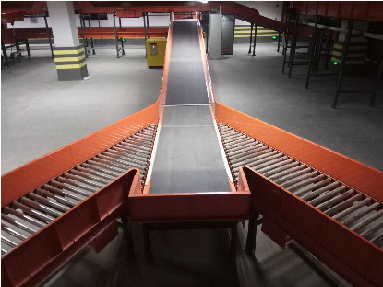

Very Narrow Aisle (VNA) pallet rack systems are designed to maximize storage density by reducing the width of the aisles required for forklifts to access pallets. These systems allow for efficient use of warehouse space while still providing selectivity and accessibility to individual pallets. Here is some information about Very Narrow Aisle pallet rack systems:

1. Aisle Width: VNA pallet rack systems feature significantly narrower aisles compared to conventional selective racking systems. The aisles typically range from 1.6 meters to 2.4 meters (5 to 8 feet) in width, depending on the specific equipment used and the requirements of the forklifts or automated guided vehicles (AGVs).

2. Specialized Forklifts or AGVs: VNA systems require specialized forklifts or AGVs that are designed to operate within the narrow aisles. These vehicles are typically equipped with unique features such as rotating masts, side-shift capabilities, or articulating forks to maneuver pallets in the tight spaces.

3. Wire or Rail Guidance: To ensure precise navigation within the narrow aisles, VNA systems often utilize wire or rail guidance systems. These systems provide a path for the forklifts or AGVs to follow, ensuring accurate positioning and minimizing the risk of collisions.

4. Height Optimization: VNA pallet rack systems are designed to maximize vertical storage space. They can be constructed to accommodate high-reaching forklifts or AGVs that can access multiple levels and handle pallets at elevated heights.

5. Selectivity and Accessibility: Despite the narrow aisles, VNA systems offer selectivity and accessibility to individual pallets. Each pallet position can be accessed directly, allowing for efficient inventory management and order picking processes.

6. Rack Configuration: VNA systems typically use specialized racking configurations, such as double-deep or very narrow aisle stacking configurations. These configurations allow for increased storage density by utilizing the space between aisles effectively.

7. Automation and Technology Integration: VNA pallet rack systems can be integrated with automation and technology solutions to further enhance efficiency. This may include automated storage and retrieval systems (AS/RS), warehouse management systems (WMS), and real-time inventory tracking, among others.

8. Safety Considerations: Due to the narrow aisles and specialized equipment used, safety is a crucial consideration in VNA systems. Adequate lighting, clear signage, and safety protocols are implemented to minimize the risk of accidents and ensure the well-being of operators and personnel working in the area.

VNA pallet rack systems are suitable for warehouses or distribution centers that require high-density storage while maintaining selectivity and accessibility to individual pallets. It is important to consult with experts in storage solutions or rack manufacturers who specialize in VNA systems to ensure that the system is designed and implemented to meet specific requirements and safety standards.