Products

Ebil Tech

Warehouse Storage Rack

Warehouse Storage Rack is one of our products, we can provide one-stop storage system solutions and products, our products also include Automated Storage for Sheet, Industrial Lift, Heavy Duty Pallet Rack System, Bars and Tubes Storage Systems, Long Material Pallet, Flat Pallet Rack Vertical, Racking System Equipment Mezzanine, Automatic Pallet Runner, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Saba Island, Azar, Barcelona (Catalonia, Spain), San Salvador (El Salvador), Georgetown (Guyana), Thailand, and so on. We are looking forward to cooperate with you. If you are interested in Warehouse Storage Rack.

Warehouse storage racks are essential components of efficient warehouse operations. They provide organized storage for various types of goods, optimize space utilization, and facilitate easy access and retrieval. Here is some information about warehouse storage racks:

1. Pallet Racking Systems:

- Selective Pallet Racking: This is the most common type of pallet racking, allowing direct access to each pallet. It is ideal for warehouses with a wide range of SKU (stock-keeping unit) sizes and high inventory turnover.

- Double Deep Racking: In this system, pallets are stored two deep, enabling higher storage density while still allowing good selectivity.

- Drive-In/Drive-Through Racking: These systems are designed for high-density storage, with forklifts driving into the racking structure to place or retrieve pallets. Drive-In racking has one entry point, while Drive-Through racking has entry points on both ends.

- Push Back Racking: This system uses inclined rails and carts, allowing multiple pallets to be stored in a single lane. When one pallet is retrieved, the others roll forward for easy access.

2. Cantilever Racking:

- Cantilever racking is designed for storing long, bulky, or irregularly shaped items such as pipes, lumber, and furniture. It consists of upright columns with horizontal arms that support the load. Cantilever racks can be single-sided or double-sided, depending on the storage requirements.

3. Shelving Systems:

- Boltless Shelving: Boltless shelving is easy to assemble and disassemble without the need for tools. It is suitable for storing light to medium loads and is commonly used in offices, stockrooms, and retail environments.

- Rivet Shelving: Rivet shelving is a cost-effective option for storing medium to heavy loads. It uses rivets or clips to secure the shelves to the uprights, providing strength and stability.

- Wire Shelving: Wire shelving is lightweight, easy to clean, and allows for good airflow and visibility. It is commonly used in food storage areas, healthcare facilities, and retail environments.

4. Mezzanine Systems:

- Mezzanines are raised platforms installed within a warehouse to create additional storage space. They can be customized to accommodate specific storage needs and can incorporate various types of racking systems, shelving, or even office spaces.

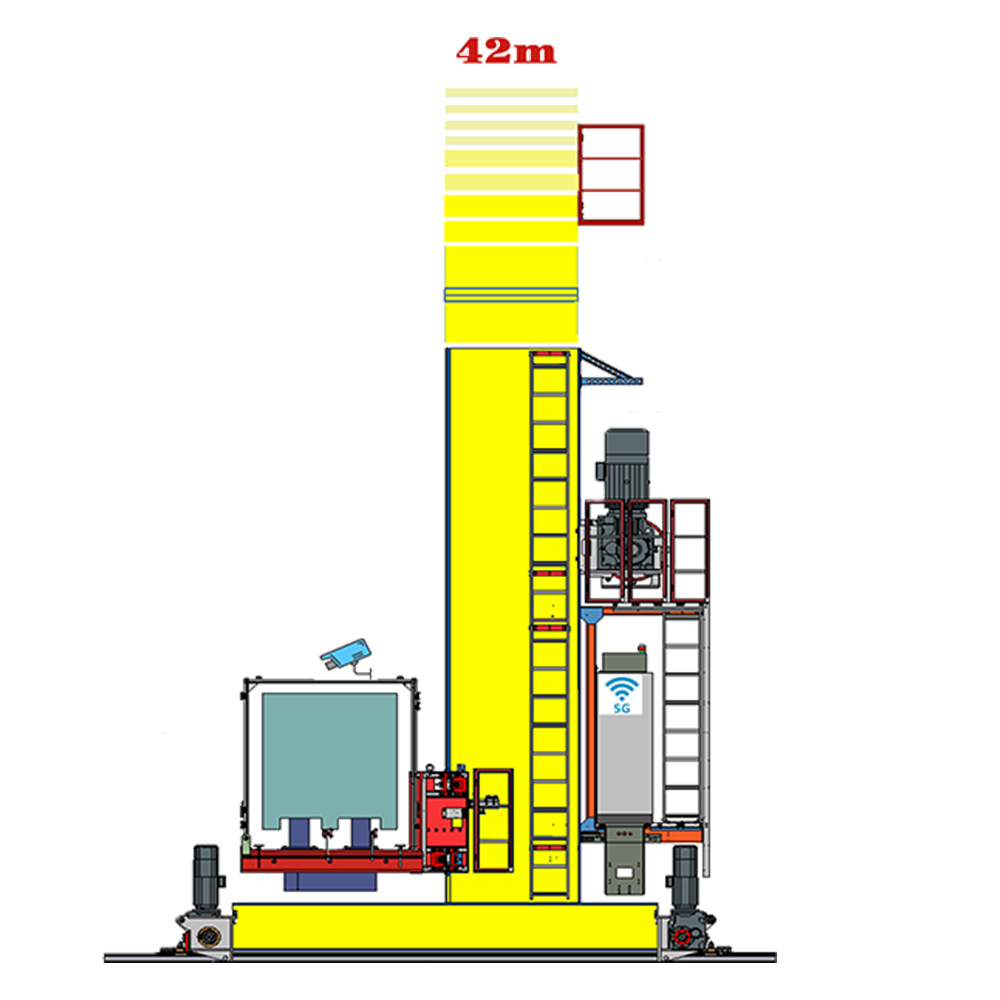

5. automated storage and retrieval systems (AS/RS):

- AS/RS are highly automated systems that use robotic mechanisms to handle the storage and retrieval of goods. They can include various types of racking or shelving systems and are commonly used in large-scale distribution centers or warehouses with high-volume operations.

When choosing warehouse storage racks, consider factors such as the type of goods, weight capacity, accessibility requirements, floor space, and future expansion needs. It is also advisable to consult with storage system experts or suppliers who can assess your specific requirements and recommend the most suitable storage solutions for your warehouse.