Products

Ebil Tech

Heavy Duty Racking

Heavy Duty Racking is one of our products, we can provide one-stop storage system solutions and products, our products also include Steel Work Platform, Steel Racking, Telescoping beam rack, Medium-Duty Racking System, Medium Duty Racking, Storage Pallet Racks, VNA Pallet Racking, Metal Radio Shuttle Racking, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Ulaanbaatar (Mongolia), Glorioso Islands, Columbus (United States), Midway Island, Riyadh (Saudi Arabia), Ogaden, and so on. We are looking forward to cooperate with you. If you are interested in Heavy Duty Racking.

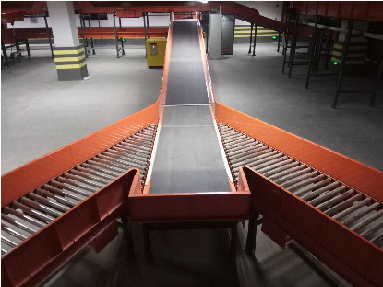

Heavy-duty racking, also known as industrial racking or heavy-duty pallet racking, is designed to handle high-capacity storage needs and support large and heavy items. It is commonly used in warehouses, manufacturing facilities, and distribution centers. Here's some information about heavy-duty racking, including profiles, types, and general pricing considerations:

1. Profile and Design:

- Heavy-duty racking is constructed with robust materials such as steel or other durable metals to ensure strength and stability.

- The design typically includes upright frames, horizontal beams, and cross-bracing for added rigidity.

- Heavy-duty racking systems are engineered to support substantial weight loads and are compatible with forklifts or other heavy-duty material handling equipment.

2. Types of Heavy-Duty Racking Systems:

- Selective Pallet Racking: Selective racking is the most common type of heavy-duty racking. It provides direct access to each pallet and is suitable for high selectivity and a wide range of SKU pallets.

- Double-Deep Racking: Double-deep racking allows for two pallets to be stored back-to-back, doubling the storage capacity while sacrificing some selectivity.

- Drive-In Racking: Drive-in racking systems maximize storage density by allowing forklifts to enter the rack structure to retrieve or deposit pallets. It is suitable for LIFO (Last In, First Out) inventory management.

- Push-Back Racking: Push-back racking utilizes inclined rails and carts that allow pallets to be stored and retrieved by pushing them back and gravity-assisted rolling. It provides high-density storage and can be used for both LIFO and FIFO (First In, First Out) inventory management.

- Pallet Flow Racking: Pallet flow racks use inclined rollers or wheels to create a dynamic flow system. Pallets are loaded from one end and flow to the other, making it suitable for FIFO storage and automatic stock rotation.

- Cantilever Racking: Cantilever racking is specifically designed for long, bulky items such as pipes, lumber, or steel bars. It features long arms extending from vertical columns, providing easy access and efficient storage for oversized items.

3. Advantages of Heavy-Duty Racking:

- High-Capacity Storage: Heavy-duty racking systems are designed to handle substantial weight loads, allowing for the storage of large and heavy items.

- Durability and Stability: These systems are built to withstand heavy loads and provide stability and safety for stored goods.

- Easy Accessibility: Heavy-duty racking enables convenient access to stored items with the use of forklifts or other appropriate material handling equipment.

- Versatility: Heavy-duty racking can accommodate a wide range of items, including pallets, long items, and bulk storage.

4. Pricing Considerations:

- Heavy-duty racking prices can vary based on factors such as the type of system, size, load capacity, material quality, and the supplier/vendor.

- Prices are typically quoted per upright frame and per pair of horizontal beams.

- Additional costs may include accessories (e.g., wire mesh decking, pallet supports), installation, and any customization requirements.

5. Customization Options:

- Heavy-duty racking systems can often be customized to meet specific storage needs, including adjusting heights, beam lengths, adding protective measures (e.g., row spacers, column guards), or incorporating accessories for specialized storage requirements.

When considering heavy-duty racking systems, it's important to evaluate factors such as the weight and size of the items to be stored, available space, accessibility requirements, and safety regulations. Consulting with suppliers or manufacturers will provide you with more detailed information and pricing based on your specific project requirements.