Products

Ebil Tech

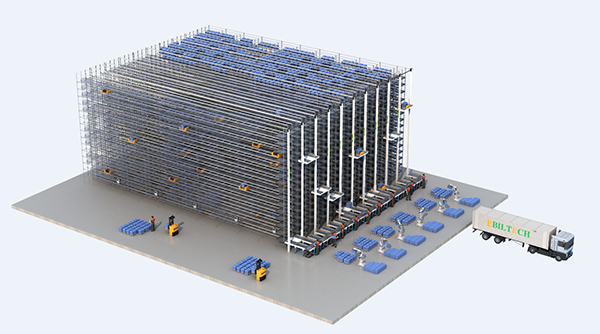

Radio Shuttle Racking

Radio Shuttle Racking is one of our products, we can provide one-stop storage system solutions and products, our products also include Eletric Double Column Stacker, Pallet Runner Racking, Cargo Elevator, Expandable cantilever rack, Material Handling Robot, Tear Drop Style Racking, Mezzanine Floors, Warehouse Flow Rack, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Warsaw (Poland), Atlanta (United States), The Hague (Netherlands), Palo Alto (United States), Valparaiso (Chile), Azores, and so on. We are looking forward to cooperate with you. If you are interested in Radio Shuttle Racking.

Radio shuttle racking, also known as shuttle pallet racking or radio shuttle system, is an automated high-density storage solution that utilizes a shuttle cart to transport pallets within a racking system. This system is designed to optimize storage capacity and improve operational efficiency in warehouses and distribution centers. Here's some information about radio shuttle racking, including an introduction, types, and general pricing considerations:

1. Introduction:

- Radio shuttle racking is a semi-automated storage system that uses a remote-controlled shuttle cart to move pallets within the racking structure.

- The shuttle cart runs on rails or tracks integrated into the racking system, allowing it to access multiple levels and storage positions.

- This system is suitable for high-density storage applications where a large number of pallets of the same SKU need to be stored and retrieved efficiently.

2. Types of Radio Shuttle Racking Systems:

- Single-Deep Radio Shuttle: In a single-deep radio shuttle system, a single shuttle cart operates within a lane, handling one pallet at a time. It is suitable for applications where high selectivity is required.

- Double-Deep Radio Shuttle: Double-deep radio shuttle systems use two shuttle carts operating in tandem to handle two pallets within a single lane. It offers higher storage density but reduces selectivity compared to single-deep systems.

- Multi-Deep Radio Shuttle: Multi-deep radio shuttle systems can handle multiple pallets within a single lane, typically up to four pallets deep. They provide even higher storage density but further reduce selectivity.

3. Advantages of Radio Shuttle Racking Systems:

- Increased Storage Density: Radio shuttle racking systems maximize storage capacity by utilizing the available vertical and horizontal space efficiently.

- Efficient Pallet Handling: The automated shuttle cart eliminates the need for forklifts to enter the racking system, reducing the time required for pallet retrieval and storage.

- Selectivity and Accessibility: Radio shuttle systems provide high selectivity, allowing access to any pallet within a lane. They can be integrated with warehouse management systems for efficient inventory control.

- Improved Safety: The automated shuttle cart reduces the risk of accidents associated with traditional forklift operations within the racking system.

4. Pricing Considerations:

- Radio shuttle racking system prices can vary based on factors such as the system type (single-deep, double-deep, or multi-deep), size, number of shuttle carts, load capacity, material quality, and the supplier/vendor.

- Prices are typically quoted based on the number of lanes, the number of shuttle carts, and the required accessories.

- Additional costs may include installation, track systems, control units, and any customization requirements.

5. Customization Options:

- Radio shuttle racking systems can often be customized to meet specific storage needs, including lane configurations, shuttle cart specifications, and integration with warehouse management systems.

When considering radio shuttle racking systems, it's important to evaluate factors such as the number of pallets to be stored, storage capacity requirements, retrieval frequency, available space, and the level of automation desired. Consulting with suppliers or manufacturers will provide you with more detailed information and pricing based on your specific project requirements.