Products

Ebil Tech

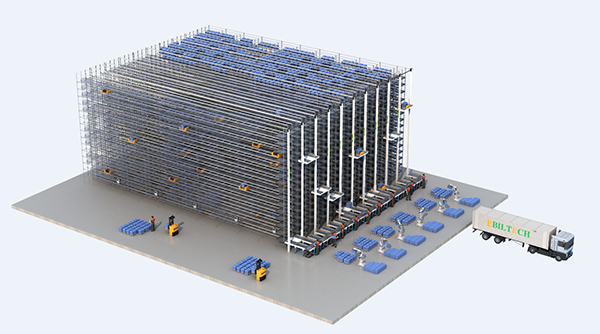

Heavy Duty Rack System

Heavy Duty Rack System is one of our products, we can provide one-stop storage system solutions and products, our products also include Shuttle Storage System, Heavy Duty Pallet Racking, Radio Shuttle Rack System, Roll Out Sheet Metal Rack, Cold Room Racking, Automatic Pallet Rack, Narrow Aisle Storage Rack, Pallet Shuttle System, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Dubai (Emirate of Dubai, UAE), Monterey (United States), Mongolia, Belize, Harare (Zimbabwe), Winnipeg (Canada), and so on. We are looking forward to cooperate with you. If you are interested in Heavy Duty Rack System.

A heavy-duty rack system is designed to support and store large, heavy items or palletized loads. These rack systems are commonly used in industrial settings, warehouses, and distribution centers where robust storage solutions are required. Here's some information on heavy-duty rack systems, including profiles, applications, types, and approximate prices:

1. Profiles:

- Upright Frames: Heavy-duty rack upright frames are typically made of high-strength steel and have a larger profile compared to standard rack systems. They provide excellent structural stability and support for heavy loads. Upright frames are available in various heights and depths to accommodate different storage requirements.

- Beams: Heavy-duty rack beams are horizontal load-bearing members that connect the upright frames. They are designed to withstand significant weight and provide a secure platform for pallets or other large items. Beams come in different lengths and load capacities to suit specific storage needs.

2. Applications:

- Heavy-duty rack systems are widely used in industries such as manufacturing, automotive, construction, retail, and logistics.

- These systems are suitable for storing heavy items, oversized goods, machinery, large components, and palletized loads.

- Heavy-duty racks are often used in warehouses and distribution centers to efficiently organize and maximize storage capacity for heavy products.

3. Types of Heavy-Duty Rack Systems:

- Selective Racking: Selective rack systems are the most common type of heavy-duty rack. They allow for direct access to each pallet or item, making it easy to retrieve individual units. This type of rack is versatile and can accommodate a wide range of load sizes and weights.

- Drive-In/Drive-Through Racking: Drive-in and drive-through rack systems are designed for high-density storage of homogeneous products with a low turnover rate. These systems allow forklifts to drive directly into the racks to deposit or retrieve pallets. Drive-in racks have one entry point, while drive-through racks have entry points on both ends.

- Push-Back Racking: Push-back racks utilize a rail and cart system that allows pallets to be stored and retrieved from one side of the rack. When a new pallet is loaded, it pushes the existing pallets back along the inclined rails. This system enables high-density storage while maintaining selectivity.

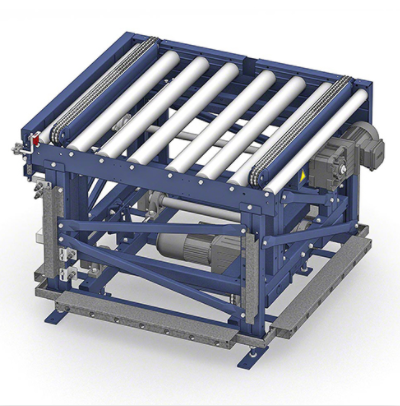

- Pallet Flow Racking: Pallet flow racks use inclined rollers or wheels to allow pallets to flow from the loading end to the unloading end by gravity. This system is suitable for high-density storage and first-in, first-out (FIFO) inventory management.

4. Approximate Prices:

- The prices of heavy-duty rack systems can vary significantly based on factors such as the type of system, dimensions, load capacity, material quality (typically high-strength steel), and the supplier/vendor.

- The approximate price range for heavy-duty rack systems is as follows:

- Selective Racking: $100 to $200 per pallet position.

- Drive-In/Drive-Through Racking: $150 to $250 per pallet position.

- Push-Back Racking: $200 to $300 per pallet position.

- Pallet Flow Racking: $250 to $350 per pallet position.

- These prices are rough estimates and may vary based on specific requirements, customization, and the supplier's pricing structure. It's advisable to consult with suppliers or manufacturers directly to obtain accurate and up-to-date pricing based on your heavy-duty rack system needs.

When considering heavy-duty rack systems, it's essential to evaluate factors such as load capacity requirements, available space, accessibility, inventory management methods (FIFO or LIFO), and any specialized needs for your specific application. Engaging with suppliers or manufacturers specializing in heavy-duty racks will provide you with more detailed information and pricing based on your project requirements.