Products

Ebil Tech

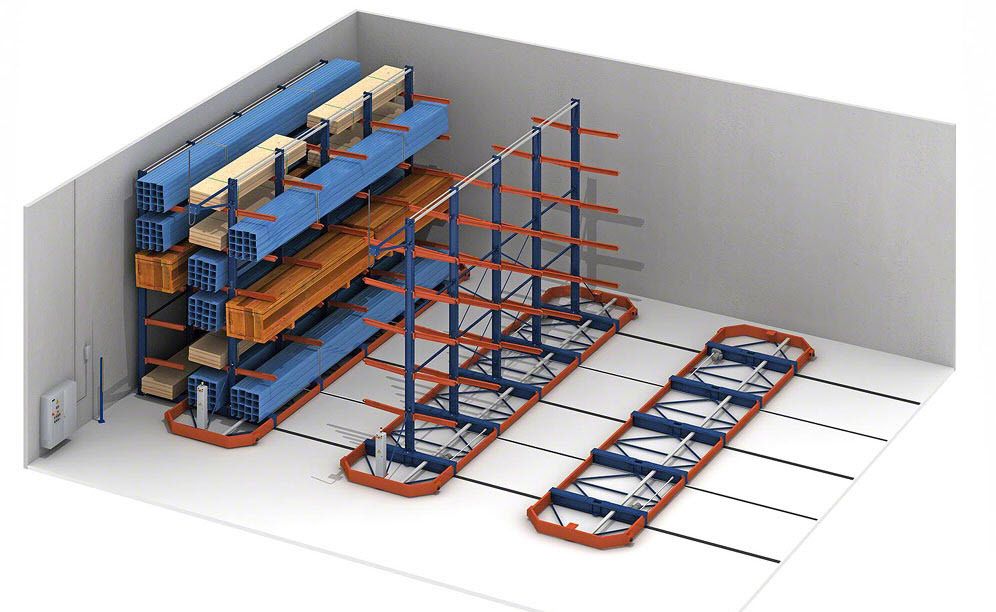

Robotic Storage Rack

Robotic Storage Rack is one of our products, we can provide one-stop storage system solutions and products, our products also include Powered telescopic arm rack, Medium-Duty Racking System, Heavy Duty Radio Shuttle Racking, Warehouse Racing, Storage Robot, Automated Shuttle Car, Electric Extendable Cantilever Shelving, Shuttle Rack, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Sao Paulo (Sao Paulo State, Brazil), Mauritania, Hannover (Germany), Fukuoka (Japan), Harare (Zimbabwe), Curitiba/Curitiba (Brazil), and so on. We are looking forward to cooperate with you. If you are interested in Robotic Storage Rack.

Robotic storage racks, also known as automated storage and retrieval systems (AS/RS) or robotic shelving systems, are advanced warehouse storage solutions that utilize robotic technology to automate the handling and retrieval of goods. These systems offer efficient and high-density storage, improved inventory management, and streamlined order fulfillment processes. Here's some information on robotic storage racks:

1. System Components:

- Racking Structure: Robotic storage racks consist of a vertical racking structure that includes multiple levels of shelves. The structure is designed to support the weight of the stored goods and provide accessibility to the robotic devices.

- Robotic Devices: The heart of the system, robotic devices are responsible for the automated movement and retrieval of goods. These robots, guided by advanced software and sensors, navigate the racking structure to access and transport items.

- Control System: A centralized control system manages the operation of the robotic devices, coordinates inventory data, and optimizes the movement and storage of goods within the system.

- Inventory Management Software: Robotic storage racks are typically integrated with inventory management software that tracks and manages inventory levels, locations, and order fulfillment processes.

2. Operation:

- Inventory Input: Goods are loaded into the robotic storage rack system at designated input stations. This can be done manually or automated through conveyor systems or other material handling equipment.

- Automated Storage: The robotic devices within the system receive instructions from the control system regarding the location and storage of each item. They autonomously navigate the racking structure, identify the appropriate shelf, and place the goods in their designated locations.

- Automated Retrieval: When an item needs to be retrieved, the robotic devices receive instructions from the control system and navigate the racking structure to the specified shelf. They pick up the requested item and transport it to the output station for further processing or order fulfillment.

- Order Fulfillment: Robotic storage racks can be integrated with other order processing technologies, such as conveyor systems or picking robots, to facilitate efficient order fulfillment. They can retrieve items and transport them to the appropriate processing area for packing and shipping.

3. Advantages:

- High-Density Storage: Robotic storage racks optimize vertical space utilization, allowing for high-density storage of goods. They can make use of the full height of the warehouse and maximize storage capacity.

- Efficient Inventory Management: With integrated inventory management software, robotic storage racks provide real-time visibility and control over inventory levels, locations, and movements. This improves inventory accuracy, reduces stockouts, and streamlines inventory replenishment processes.

- Increased Throughput: The automated nature of robotic storage racks enables faster and more efficient handling and retrieval of goods, leading to increased throughput and improved order processing times.

- Space Optimization: Robotic storage racks can be customized to fit the available space and specific storage requirements. They can be designed to accommodate different item sizes and shapes, further optimizing space utilization.

- Enhanced Safety: By automating material handling processes, robotic storage racks reduce the need for manual interventions and minimize the risk of accidents or injuries associated with traditional manual operations.

4. Applications:

- E-commerce and Retail: Robotic storage racks are commonly used in e-commerce and retail warehouses to handle high volumes of inventory and streamline order fulfillment processes.

- Manufacturing: These systems can be implemented in manufacturing facilities to store and retrieve raw materials or components, optimizing production line efficiency.

- Cold Storage: Robotic storage racks can be utilized in temperature-controlled environments, such as cold storage warehouses, to automate the storage and retrieval of perishable goods.

- Logistics and Distribution: They are suitable for logistics and distribution centers, where efficient storage and retrieval of goods are crucial for timely order processing and delivery.

5. Pricing:

- The cost of robotic storage rack systems can vary significantly depending on factors such as the size of the system, number of robotic devices, level of automation, and customization requirements.

- Prices typically include the cost of the racking structure, robotic devices, control system, and integration with inventory management software.

- It is recommended to consult with suppliers or manufacturers of robotic storage rack systems to obtain accurate pricing information based on your specific needs and requirements.

When considering the implementation of robotic storage racks, it is important to evaluate factors such as the volume and variety of goods to be stored, the required throughput, available space, and integration with existing warehouse management systems. Working with experienced suppliers or consultants specializing in automated storage systems will help determine the most suitable configuration and provide detailed information tailored to your specific needs.