Products

Ebil Tech

Warehouse Equipment

Warehouse Equipment is one of our products, we can provide one-stop storage system solutions and products, our products also include Honeycomb Rack, RGV System, Fifo Rack, Automatic long bars storage system, Roll-Out Rack with manual extraction, Storage Laneway Shuttle, Roll Out Sheet Racks, Mid-Duty Shelving, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Thailand, Komi, Yangon (Myanmar), Israel, Curitiba/Curitiba (Brazil), Mali, and so on. We are looking forward to cooperate with you. If you are interested in Warehouse Equipment.

Warehouse equipment refers to a wide range of tools, machinery, and devices used in warehouses or distribution centers to facilitate material handling, storage, and logistics operations. These equipment are designed to improve efficiency, productivity, and safety within the warehouse environment. Here are some common types of warehouse equipment:

1. Forklifts: Forklifts are versatile industrial vehicles used for lifting and moving heavy loads. They feature two forks at the front that can be raised or lowered to lift and transport pallets, containers, or other materials.

2. Pallet Jacks: Pallet jacks, also known as pallet trucks or pump trucks, are manual or electric-powered devices used to lift and move pallets. They have forks that slide under pallets, allowing for easy maneuvering within the warehouse.

3. Conveyor Systems: Conveyor systems are automated or semi-automated machines used to transport goods or materials along a fixed path. They consist of belts, rollers, or other mechanisms that move items from one location to another, reducing the need for manual handling.

4. Shelving and Racking Systems: Shelving and racking systems provide storage space for goods or materials in a warehouse. They include various types such as pallet racking, cantilever racks, mezzanine systems, and wire shelving, allowing for efficient organization and utilization of warehouse space.

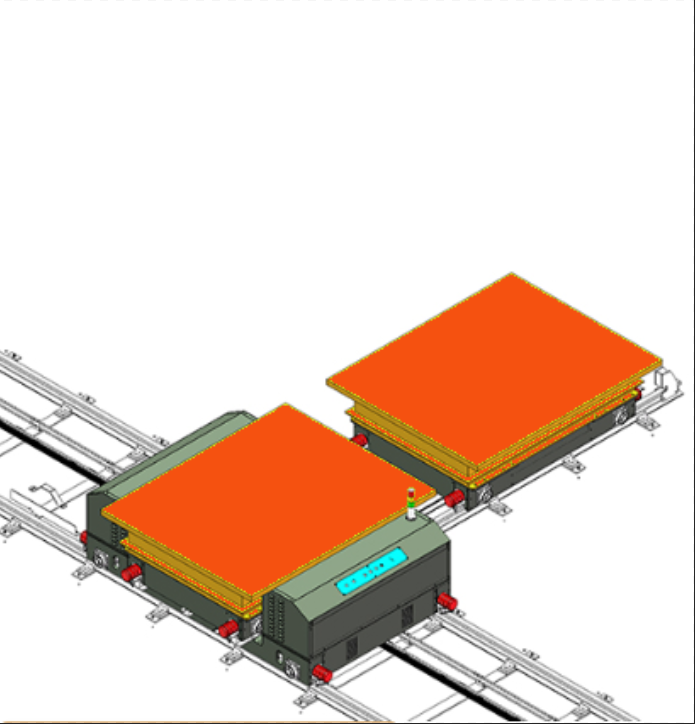

5. automated storage and retrieval systems (AS/RS): AS/RS systems are robotic systems used for automated storage and retrieval of goods. They typically consist of stacker cranes, shuttles, or robotic arms that move within the racking system to retrieve and store items.

6. Order Picking Equipment: Order picking equipment includes tools and devices used to fulfill customer orders by selecting items from the warehouse shelves or racks. This may include pick-to-light systems, voice-guided picking systems, or handheld scanners.

7. Packaging Equipment: Packaging equipment is used to prepare items for shipment or storage. It includes machines such as stretch wrappers, palletizers, strapping machines, and labeling systems, which automate packaging processes.

8. Dock Equipment: Dock equipment is used to facilitate loading and unloading operations at warehouse docks. This includes dock levelers, dock seals, dock shelters, and dock plates/ramps, ensuring safe and efficient movement of goods between trucks and the warehouse.

9. Material Handling Carts and Trolleys: Material handling carts and trolleys are used to transport smaller items or packages within the warehouse. They come in various designs, including platform carts, shelf carts, and hand trucks.

10. Safety Equipment: Safety equipment is essential in warehouses to protect workers and prevent accidents. This may include safety barriers, guardrails, personal protective equipment (PPE), fire extinguishers, and safety signs.