Cases

- Client:

- Area:

- Date: 0000-00-00

- Products:

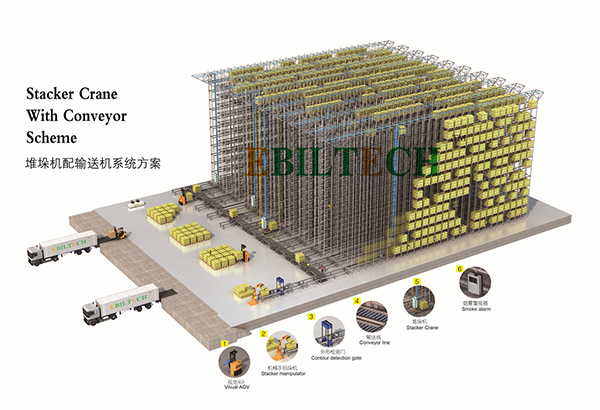

LG project

The LG project involves several new energy warehouses and EBIL TECH customized an intelligent warehousing solution for LG. In this intelligent warehouse, a combination of welded racks and stackers is used in the storage system which provides high efficiency storage equipment and software support for LG intelligent warehouse. The intelligent warehouse of the stacker has high storage density and warehouse utilization, low comprehensive investment cost, flexible planning, and many system layout options. Through WMS management and WCS scheduling to realize the warehouse unmanned operation, automatic data backup, to ensure the consistency of accounts and materials data. New energy Automated Warehouses use laneway stackers automatic warehouse operation equipment. Its overall composition is mainly composed of buildings, shelves, trackless laneway stackers, tally area, management area, and supporting machinery. According to the different structure of the shelves, there can be various layout forms, and the most common layout form is the unit-cargo lane automatic warehouse. In the design of automated warehouses, properly determining the size of the cargo position is a very important design content, which is directly related to the utilization rate of the warehouse area and space, as well as whether the equipment can successfully complete the storage and retrieval operations. The value of the gap is mainly determined by the rack installation error, the deformation of rack and other equipment when loaded, the control mode of stacker (manual or automatic), installation error, positioning accuracy, and the deflection deformation of the upright. Generally speaking, the smaller the clearance is, the higher the accuracy and deformation requirements of the equipment. Conversely, the larger the clearance, the easier it is to enter and exit goods. Under the premise of ensuring the smooth progress of the warehouse operation, the gap size should be minimized to help improve the space utilization of the warehouse.

EBIL TECH provides automated warehouse and logistics system solutions that save manpower and material resources to industries such as new energy industry, manufacturing, food, tobacco, automobiles and electronics, medicine, chemistry, and cold chain.

Ebil Tech Products

Get a quote

The professional supplier that provide intelligent intensive storage equipment and system solutions.