The use of ASRS in automated warehouses

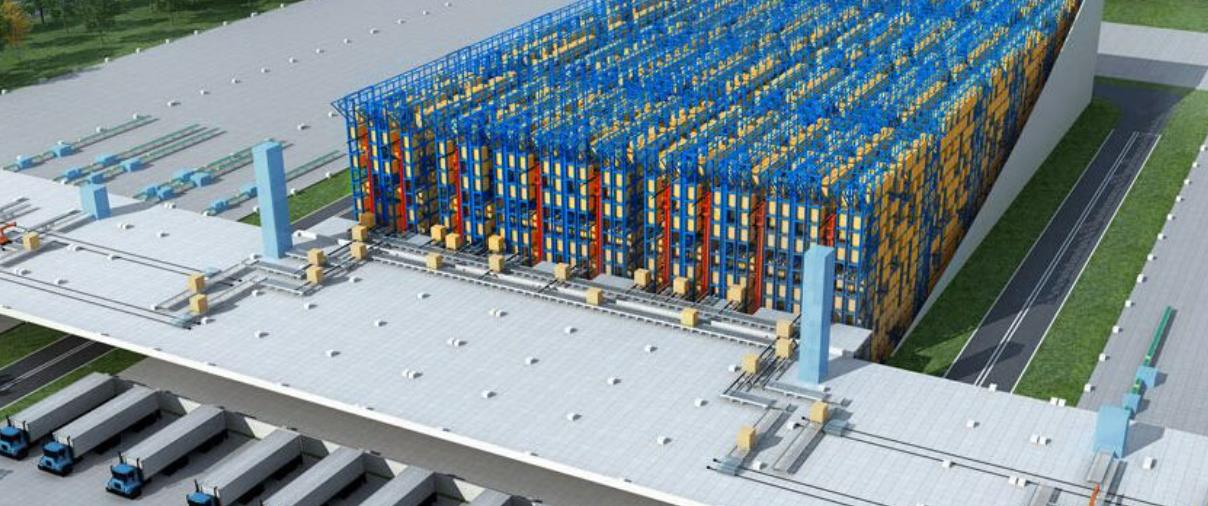

ASRS system, in simple terms, is the abbreviation for automated three-dimensional warehouse. It mainly includes high-level three-dimensional shelves, storage pallets, material boxes, stackers, forklifts, automated conveyor lines, WMS systems, and management control systems. The ASRS system is a warehouse form aimed at saving space resources, improving warehousing efficiency, and enhancing warehousing management level. The entire warehousing chain is fully automated, without the need for manual operation, reducing manual errors, improving warehousing efficiency while reducing labor costs. The vigorous development of automated warehouses is an inevitable trend of historical progress.

ASRS (Automated Storage and Retrieval System) plays a crucial role in automated warehouses by providing efficient storage and retrieval of goods. Here's a look at how ASRS is used in automated warehouses:

1. Storage Optimization: ASRS systems optimize storage space by utilizing vertical height. They make use of high-rise racking structures that can be several stories tall, maximizing the available vertical space in the warehouse. ASRS systems enable denser storage compared to traditional racking systems, allowing warehouses to store a larger volume of goods in a smaller footprint.

2. Automated Storage: ASRS systems automate the storage process by using specialized machinery, such as stacker cranes or robotic systems, to handle the movement and placement of items into designated storage locations. These machines are equipped with sensors, cameras, and computer-controlled systems to accurately position and store items in the appropriate locations within the racking structure. ASRS systems eliminate the need for manual labor in the storage process, reducing human error and increasing efficiency.

3. Retrieval and Order Fulfillment: ASRS systems excel in retrieving items from storage quickly and accurately. When an order is placed, the ASRS system identifies the location of the requested item and automatically retrieves it using the appropriate machinery. This retrieval process is typically carried out by stacker cranes or robotic arms that extract the item from its storage location and transport it to a designated area for further processing or shipping.

4. Inventory Management: ASRS systems integrate with warehouse management systems (WMS) to provide real-time inventory management capabilities. The ASRS system tracks the location, quantity, and status of each item stored in the warehouse, enabling accurate inventory control and visibility. This helps warehouses maintain optimal inventory levels, reduce stockouts, and streamline inventory replenishment processes.

5. Order Picking and Sorting: ASRS systems can be integrated with automated sorting and picking systems to further enhance warehouse operations. After retrieving the requested items, the ASRS system can direct them to specific picking stations or sorting areas using conveyors or robotic systems. This streamlines the order fulfillment process, reduces manual labor requirements, and improves order accuracy.

6. Warehouse Control System (WCS) Integration: ASRS systems are managed and controlled by a WCS, which acts as the central control unit. The WCS coordinates and synchronizes the operation of ASRS machinery, conveyors, sorting systems, and other components of the automated warehouse. It ensures efficient communication and manages the flow of goods throughout the warehouse, optimizing overall system performance.

By incorporating ASRS systems into their operations, automated warehouses benefit from increased storage capacity, improved efficiency, accurate inventory management, and streamlined order fulfillment. ASRS technology enables warehouses to handle large volumes of goods, reduce labor costs, minimize errors, and enhance overall operational productivity.

ASRS systems are utilized in a wide range of industries where efficient and automated warehousing solutions are required. Here are some examples of industries that commonly use ASRS systems in their warehouses:

1. E-commerce and Retail: With the rise of online shopping, e-commerce companies and retail giants often rely on ASRS systems to handle their vast inventories. ASRS technology enables efficient storage and retrieval of products, streamlining order fulfillment processes and ensuring fast and accurate delivery to customers.

2. Manufacturing and Industrial: Manufacturing industries, including automotive, electronics, and consumer goods, often implement ASRS systems to manage their raw materials, components, and finished goods. ASRS solutions help optimize inventory management, reduce production downtime, and enhance supply chain efficiency.

3. Food and Beverage: ASRS systems are widely used in the food and beverage industry to manage perishable items and optimize their storage and retrieval. ASRS technology ensures proper rotation of inventory based on expiration dates, facilitates efficient picking for order assembly, and maintains strict inventory control for compliance with food safety regulations.

4. Pharmaceutical and Healthcare: The pharmaceutical and healthcare sectors require precise inventory management and strict adherence to regulatory standards. ASRS systems provide automated storage and retrieval of pharmaceuticals, medical devices, and healthcare supplies, ensuring accurate tracking, efficient order fulfillment, and adherence to industry-specific regulations.

5. Third-Party Logistics (3PL): 3PL providers often employ ASRS systems to efficiently manage and store goods for multiple clients. ASRS technology enables the segregation and retrieval of specific items for different clients, ensuring accurate inventory management and timely order fulfillment for diverse product portfolios.

6. Cold Storage and Freezing Facilities: ASRS systems are employed in cold storage and freezing facilities to automate the storage and retrieval of temperature-sensitive goods such as frozen food, perishable items, and pharmaceuticals. These systems help maintain the integrity and quality of products while optimizing space utilization in temperature-controlled environments.

7. Automotive and Spare Parts: The automotive industry extensively uses ASRS systems to manage the storage and retrieval of automotive parts and components. ASRS technology ensures efficient handling of a wide range of parts, reduces picking errors, and supports just-in-time inventory management practices.

These are just a few examples of industries that commonly leverage ASRS systems in their warehouses. ASRS technology has broad applicability and can be tailored to meet the specific requirements of various industries, making it a versatile solution for automated warehousing.