- Home

- About Us

- Products

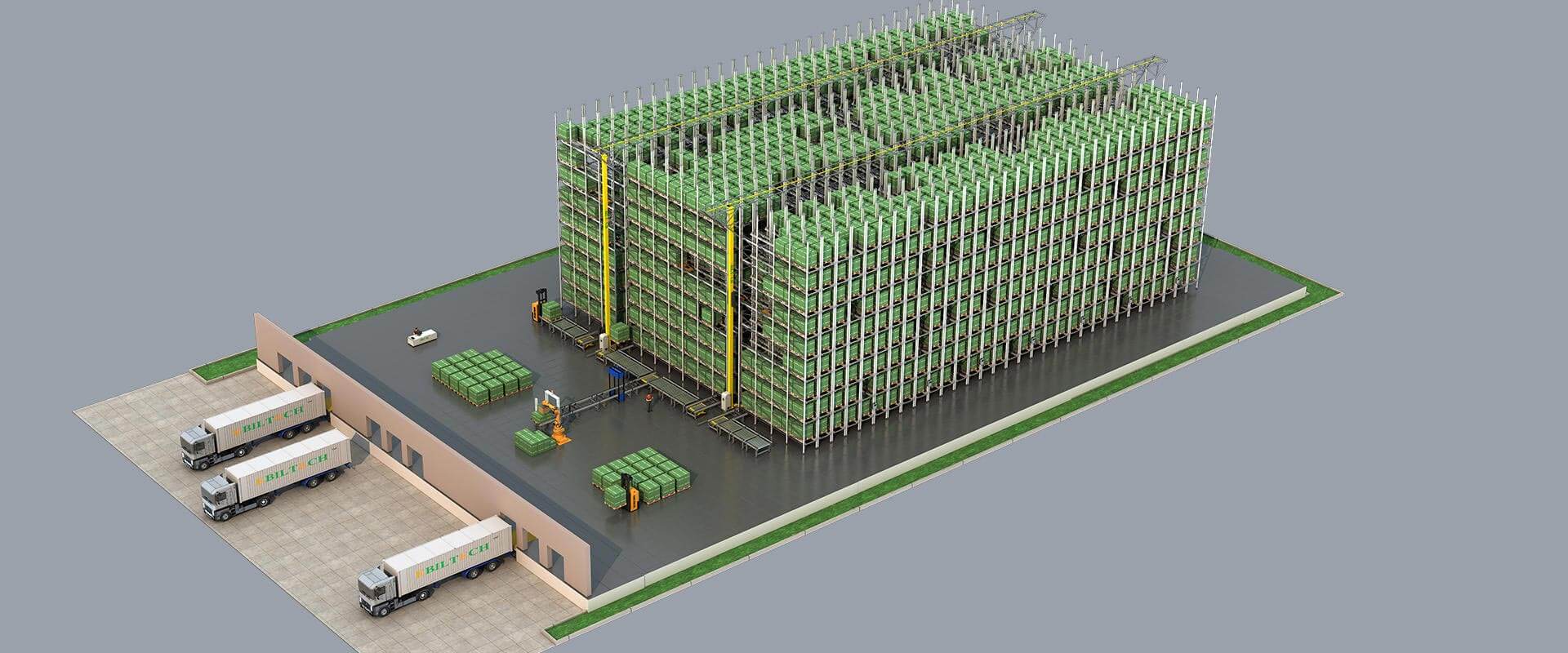

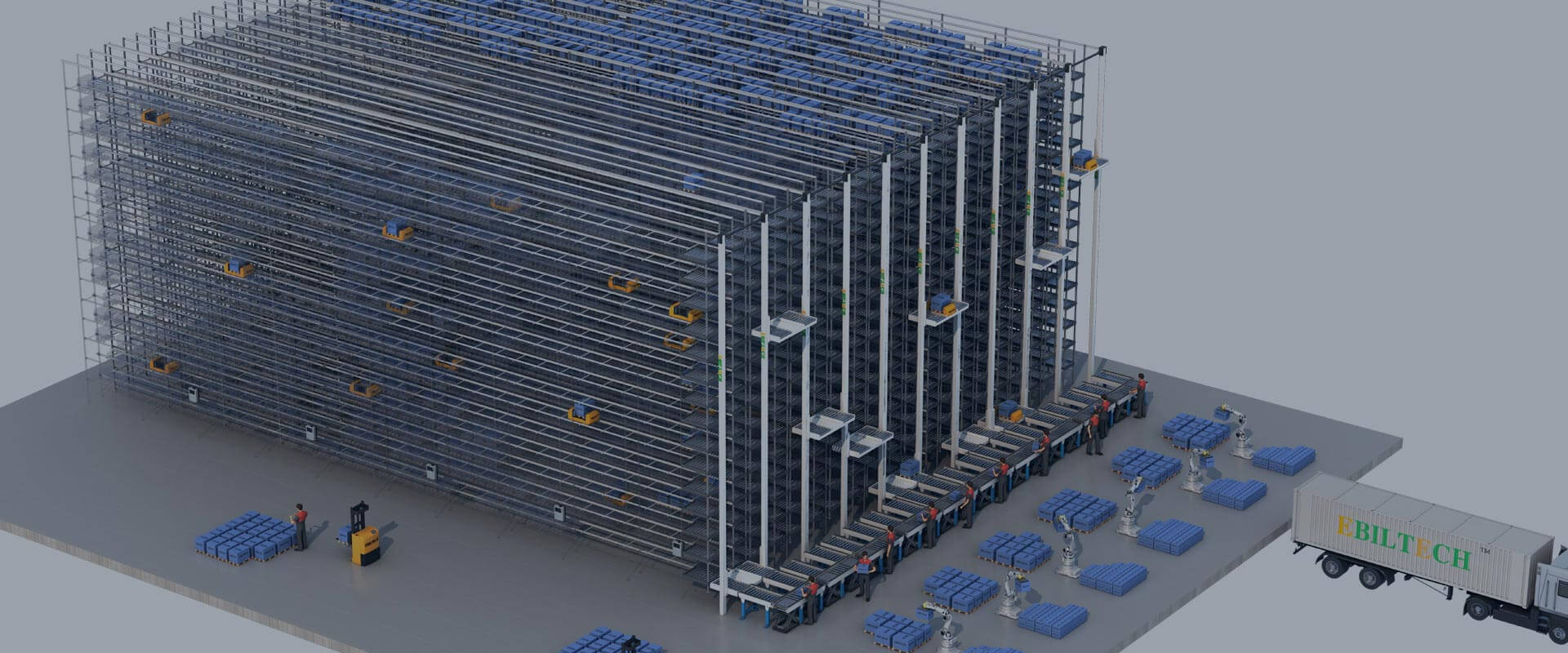

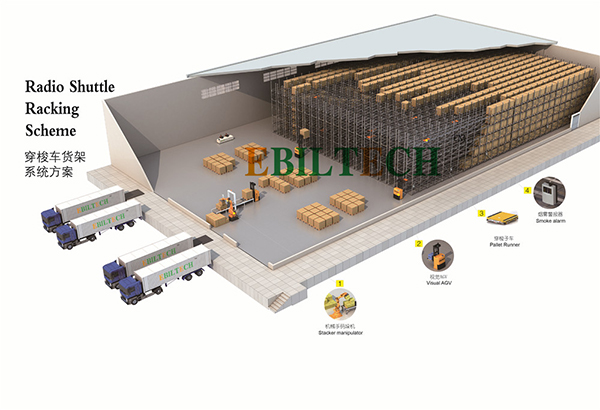

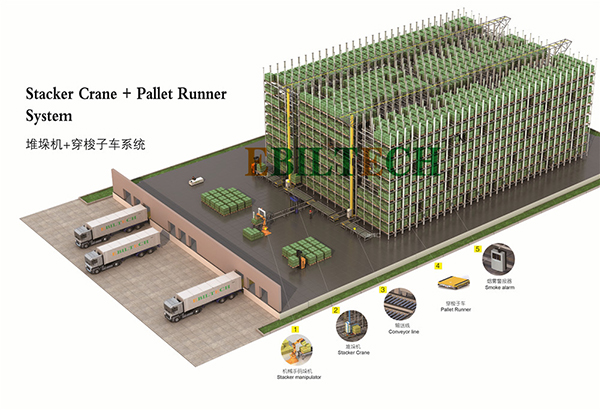

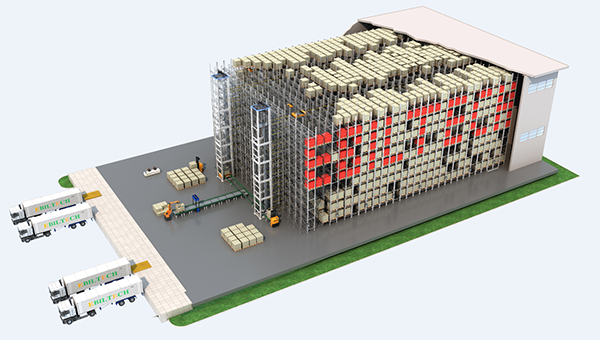

- Automated Storage & Retrieval Systems

- Automation Equipment Series

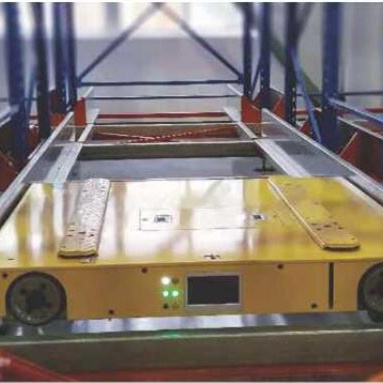

- Two Way Radio Shuttle

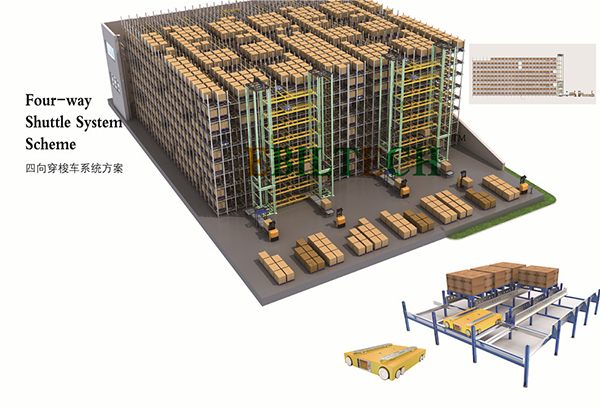

- Four-way Shuttle

- Multi-deck Shuttle carrier

- Mother-Child Shuttle

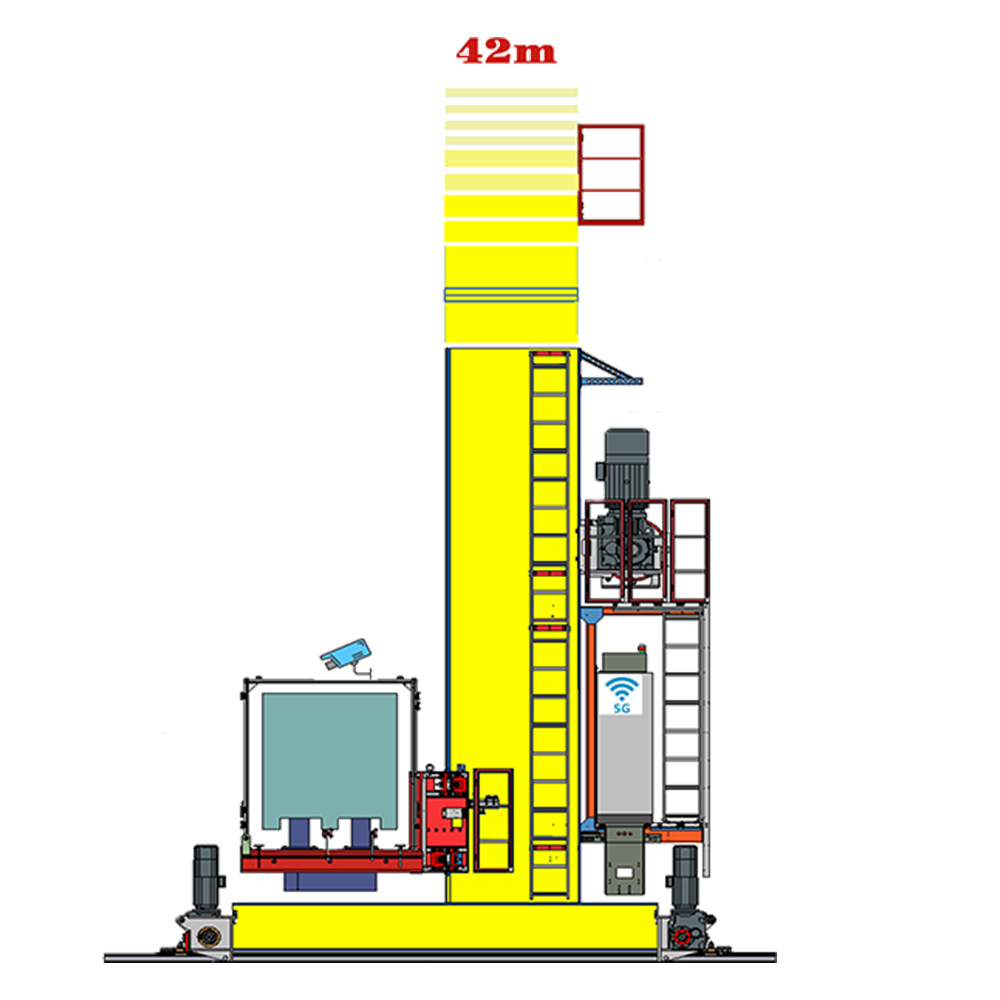

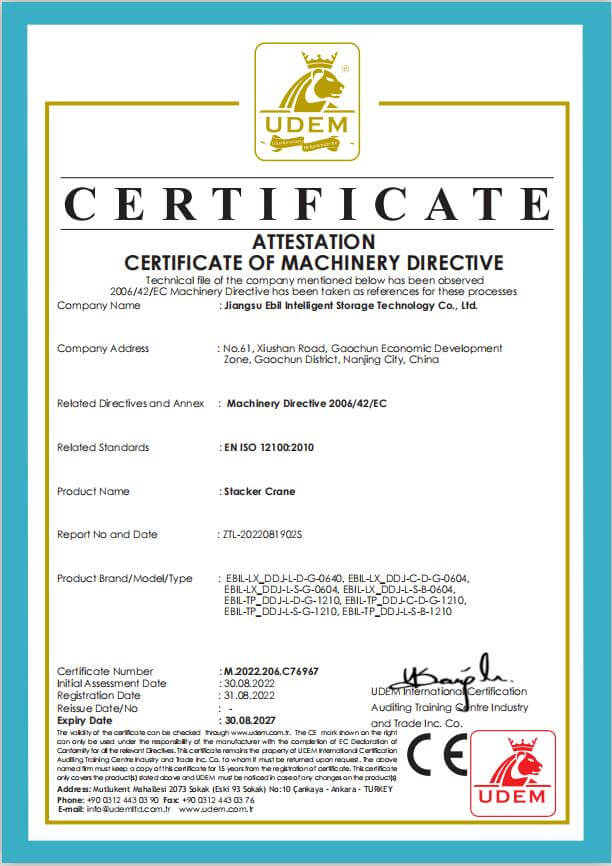

- Stacker Crane

- Cargo Elevator

- Ring-type RGV shuttle

- Heavy-duty traverse type RGV shuttle

- Box chain conveyor

- Carton turntable conveyor

- Pallet chain conveyor

- Carton Jack-up conveyor

- Straight line RGV shuttle

- Belt conveyors

- Box roller conveyor

- Automatic sorting system

- Pallet stacker dispenser

- Conveyor system

- Pallet dispenser

- Pallet roller conveyor

- Pallet Jack-up conveyor

- Palletizer

- Pallet turntable conveyor

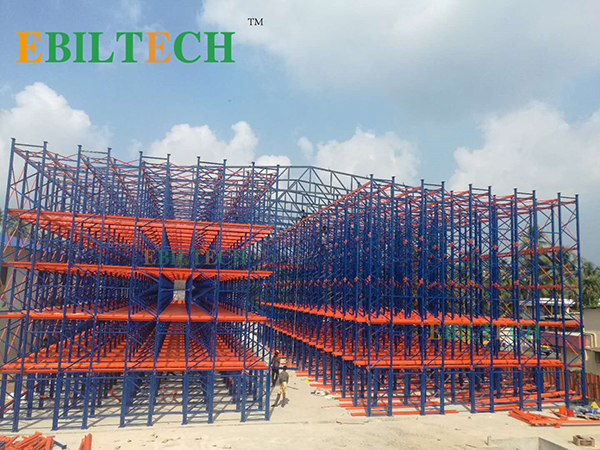

- High Intensive Racking

- Long Material Racks

- Standard Rack Series

- Logistics Supporting Equipment

- Warehouse Protection Series

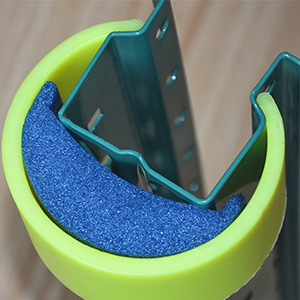

- The first generation of plastic upright protector

- The Third generation of plastic upright protector

- The fourth generationof plastic upright protector

- The fifth generation of plastic upright protector

- The sixth generation of plastic upright protector

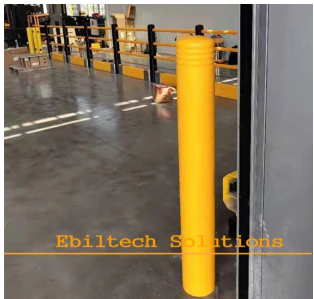

- Protective Bollards

- Guardrail

- Elastic protective pile

- Goal Post

- Intelligent racking warning light

- Automated Soilless Cultivation

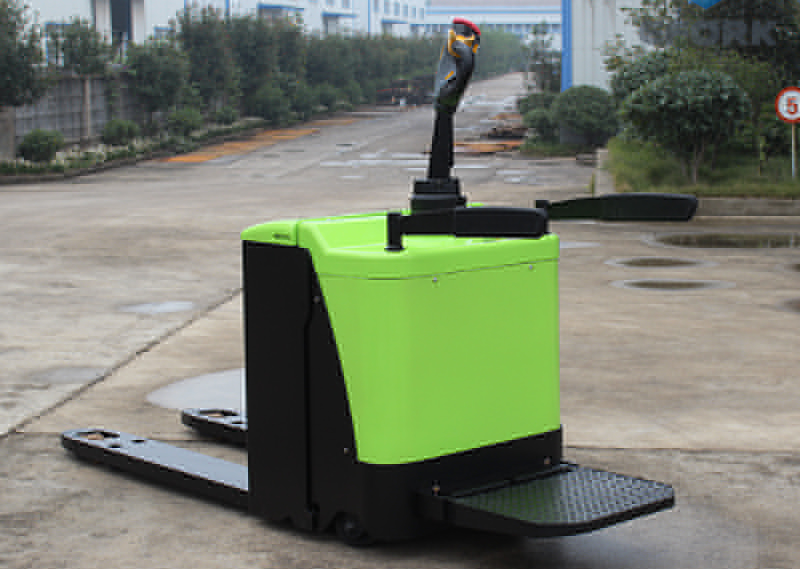

- Forklift Series

- Maint of AS/RS

- Team

- News

- Cases

- Contact Us

- Online Mail

- Home

- About Us

- Products

- Automated Storage & Retrieval Systems

- Automation Equipment Series

- Two Way Radio Shuttle

- Four-way Shuttle

- Multi-deck Shuttle carrier

- Mother-Child Shuttle

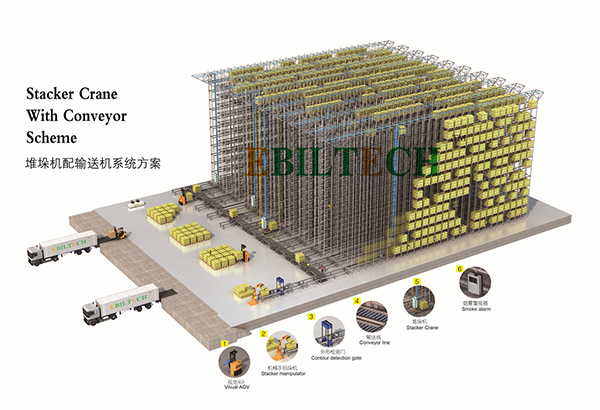

- Stacker Crane

- Cargo Elevator

- Ring-type RGV shuttle

- Heavy-duty traverse type RGV shuttle

- Box chain conveyor

- Carton turntable conveyor

- Pallet chain conveyor

- Carton Jack-up conveyor

- Straight line RGV shuttle

- Belt conveyors

- Box roller conveyor

- Automatic sorting system

- Pallet stacker dispenser

- Conveyor system

- Pallet dispenser

- Pallet roller conveyor

- Pallet Jack-up conveyor

- Palletizer

- Pallet turntable conveyor

- High Intensive Racking

- Long Material Racks

- Standard Rack Series

- Logistics Supporting Equipment

- Warehouse Protection Series

- The first generation of plastic upright protector

- The Third generation of plastic upright protector

- The fourth generationof plastic upright protector

- The fifth generation of plastic upright protector

- The sixth generation of plastic upright protector

- Protective Bollards

- Guardrail

- Elastic protective pile

- Goal Post

- Intelligent racking warning light

- Automated Soilless Cultivation

- Forklift Series

- Maint of AS/RS

- Team

- News

- Cases

- Contact Us

- Online Mail